Home » water cooled chillers

Articles Tagged with ''water cooled chillers''

Representing a key milestone in its growth strategy

Read More

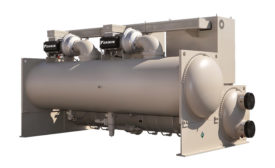

Finding the Right Chiller for the Job

Fuel availability, efficiency, and compressor type all play roles in buyers’ decisions

Read More

Efficiency, Innovation Define HVAC Chillers

Manufacturers strive for greater part-load efficiency, enhanced monitoring, improved serviceability

Read More

Ilios Inks Rep Agreement and Sale with Sam DeSanto Co.

Order Placed for an Ilios Water-Source High-Efficiency Water Heater

August 11, 2014

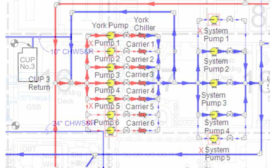

July 1, 2013: Chilled Water Retrofit Earns Energy Efficiency Awards

Projected Annual Savings of $1.3 Million in Utility Costs

July 1, 2013

Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing