Home » VFD (variable-frequency drive)

Articles Tagged with ''VFD (variable-frequency drive)''

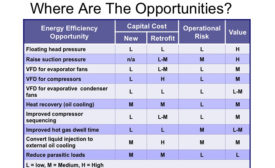

10 Tips to Increase System Efficiency

Read More

April 10, 2015: DrivePak Earns Top Product of the Year Award from Environmental Leader

DrivePak Recognized for Delivering Energy, Environmental Benefits

April 10, 2015

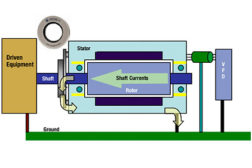

Preventing Electrical Fluting in Motors

Ceramic Ball Bearings, Shaft Grounding Rings Help Mitigate Damage

Read More

Nov. 14, 2013: AHRI Launches Certification Programs for VFDs and Datacom Cooling

AHRI Manages 40 Performance Certification Programs for HVACR and Water Heating Products

November 14, 2013

Congressman Talks Energy with Danfoss

Discusses Legislation to Advance Energy-Efficient and Renewable Energy Technologies

September 2, 2013

Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing