Home » The Professor

Articles Tagged with ''The Professor''

These valuable components keep systems clean but can become restricted themselves

Read More

The Professor: The Perils of Overcharging

Too much refrigerant can cause a number of system issues

Read More

The Professor: More Troubleshooting Tips for Spring Tuneups

Properly diagnosing the symptoms is what sets professional technicians apart

Read More

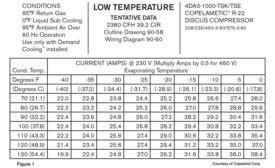

The Professor: Understanding Compressor Amperage Curves

Table-style charts are easy to read and provide valuable information about system function

Read More

The Professor: The Importance of a Refrigeration System’s Operating Pressures

Calculating and analyzing compression ratios can aid system troubleshooting

Read More

The Professor: Calculating Net Temperature Glide

Simple calculations account for system pressure drop

Read More

The Professor: The Correlation Between Refrigerant Blends and Temperature Glide

Composition of the liquid and vapor phases differ due to phase changes

Read More

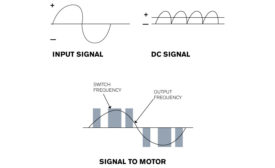

The Professor: Controlling Motor Speed with VFDs

Benefits include improved comfort and energy efficiency

Read More

The Professor: Foiling Frosted Evaporator Coils

Reduced airflow over the coil can cause a multitude of woes

Read More

The Professor: Symptoms of Air in a Refrigeration System

Air May Cause a Reduction in Condensing Surface Area and High Head Pressures

Read More

Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing