Service and Maintenance

How to Clean Coils and Make More Money While Doing It

Mutually beneficial maintenance procedure improves comfort, efficiency

Read More

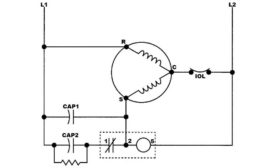

5 Capacitor Facts You Should Know

These facts will come in handy during diagnosis and replacement

Read More

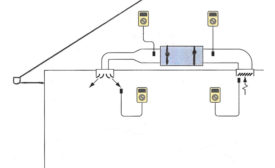

Leak Detector Maintenance and Care

Quality care and testing will help find leaks the first time

Read More

A Comfort Complaint Follow-Up

Is it the equipment or the service that's causing the performance issues?

Read More

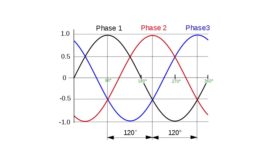

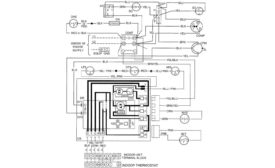

Three-Phase Power and Voltage Imbalances

A little electrical knowledge can go a long way in troubleshooting HVAC systems

Read More

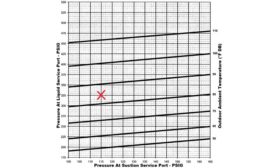

A Heat Pump That's Not Keeping an Office Warm

The temperature on the thermostat does not match the temperature of the conditioned space

Read More

A Frozen Coil Can Hinder A/C System Effectiveness

Ice forms on the heat exchanger and acts as an insulator

Read More

Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing