Refrigeration

I’m honored to be part of New York City’s first technical school

Read More

Rick Downie Earns Runner-up in Best Trainer Competition

Bard’s manager of technical education trains everyone, everywhere, on everything

Read More

Supermarket Conference Features Refrigeration Track, Networking Opportunities

Orlando to host FMI Energy and Store Development Conference

September 5, 2017

Hudson Technologies to Acquire Airgas Refrigerants

Expanded geographic footprint, customer base, and sales and distribution capabilities cited

September 5, 2017

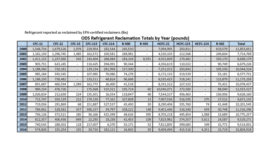

EPA Releases 2016 Refrigerant Reclamation Numbers

10.8 million lbs. is an increase of 1.3 million lbs.over 2015

September 5, 2017

Two Views of the DC Court’s HFC Ruling

The EPA can’t use SNAP to phase down HFCs –is that a pointless sidetrack or a wise slowdown?

Read More

Seeking Sustainability in Supermarkets

Contractors promote savings via integrated controls, optimized compressor runtimes, and more

Read More

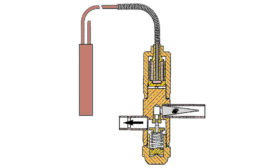

Liquid Injection Takes the Heat Off Compressors

TREVs continue to be effective problem-solving tools for new refrigerants

Read More

Dealing With an Inefficient Refrigeration Compressor

High suction pressure plus low head pressure can risk product quality and safety

Read More

Danfoss Opens Application Development Center in Florida

The Tallahassee center features three fully automated test facilities

Read More

Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing