Articles by John Tomczyk

From vapor compression to evaporative cooling, R-718 is still a viable option

Read More

The Professor: Global Warming Scares Costing Us Some Popular Refrigerants

Many refrigerants have been delisted in certain applications

Read More

The Professor: The Importance of the Condenser

Condensers perform three vital functions, so keep them clean and damage-free

Read More

The Professor: How Airflow Woes Can Affect Refrigerant Flow

Low suction and head pressures might just be a dirty filter, not a refrigerant undercharge

Read More

The Professor: More Troubleshooting Tips for Spring Tuneups

Properly diagnosing the symptoms is what sets professional technicians apart

Read More

The Professor: In Spring, Thoughts Turn to Troubleshooting

Spotting problems now will help you get a/c systems ready for cooling season

Read More

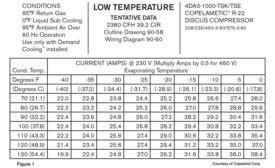

The Professor: Understanding Compressor Amperage Curves

Table-style charts are easy to read and provide valuable information about system function

Read More

The Professor: The Importance of a Refrigeration System’s Operating Pressures

Calculating and analyzing compression ratios can aid system troubleshooting

Read More

Refrigeration Zone

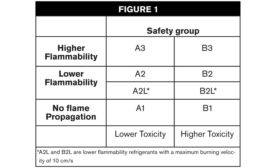

The Professor: The Art and Science of Creating Refrigerant Blends

Each component brings its own characteristics to the final mixture

Read More

The Professor: Calculating Net Temperature Glide

Simple calculations account for system pressure drop

Read More

Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing