Home » Keywords: » soldering and brazing

Items Tagged with 'soldering and brazing'

ARTICLES

Installing Thermostatic Expansion Valves

Don’t assume the TXV is properly adjusted from the manufacturer

Read More

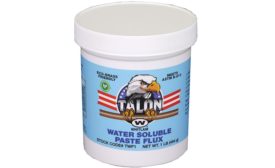

Don’t Be Brazen When It Comes to Soldering and Brazing Techniques

Use these best practices for the best results

Read More

How to Solder No-Lead Fittings

Contractors need to make sure these 10 things happen

November 7, 2016

Uniweld Releases Instructional Video on Joining Aluminum Tubes to Dissimilar Metals

Demonstrates how to join aluminum to copper using company’s soft solder kit

January 29, 2016

New Soldering Procedure Available from NCPWB

Procedure is in accordance with ASTM B-828

January 22, 2016

Recommended Practices for Soldering No-Lead Copper Alloys

Legislation Prompts CDA to Revisit Soldering Techniques for Making Proper Joints

December 8, 2014

Ice Breaker: Brazing and Soldering Procedures Need Care

Tips for Working Safely with Torches

Read More

Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing