- NEWS

- MEDIA

- REFRIGERATION

- BUSINESS 101

- RESIDENTIAL

- COMMERCIAL

- DIRECTORY

- MORE

- INFOCENTER

- MEDIA GROUP

- MAGAZINE

Home » Keywords: » make-up air

Items Tagged with 'make-up air'

ARTICLES

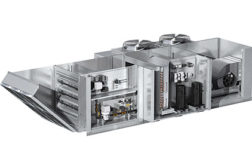

Modine Offers New Direct Fired Make-Up Air Unit

The new units are available with two model options, MCV and MVV

January 4, 2017

Overcoming Residential Makeup Air Challenges

Exhaust makeup air solution meets standards, satisfies homeowners’ needs

March 14, 2016

Oct. 16, 2014: enVerid Systems Receives DOE Funding for Energy-Saving HVAC Technology

Intelligent, Modular, Low-Cost Scrubber Can Be Retrofitted or Used in New Construction

October 16, 2014

Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing