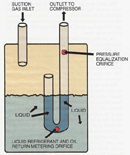

Figure 1. This illustration shows the gauges connected to the refrigerant cylinder with the nitrogen cylinder ready to connect. (Figures are from Refrigeration & Air Conditioning Technology, 5th Edition, by William Whitman, William Johnson, and John Tomczyk, published by Thomson Delmar Learning.) (Click on the image for an enlarged view.)

Btu Buddy said, “The system is in a vacuum after the recovery. What are you going to do next?”

Bob said, “Just open the valves and let air in. We are going to evacuate the system anyway.”

Btu Buddy then said, “Turn off the power first and lock the disconnect switch. Then the system should be brought back up to atmospheric pressure with dry nitrogen. If just air is let into the system, the air will contain oxygen that will mix with any acid in the system and could cause corrosion, so a good practice is to fill the system with nitrogen (Figure 1). Recovering the refrigerant and pulling the system into a vacuum removes all refrigerant, but acid will remain in any oil that is left in the system coils and piping.”

Figure 2. The only line that remains a permanent suction line is the line between the four-way valve and the compressor. The filter must be located in this line. Any other location would subject the filter to high pressures during one of the heat pump cycles. (Click on the image for an enlarged view.)

Bob then loosened the hold down bolts to the compressor base and removed them so the compressor could be lifted from the cabinet. He already had the wiring disconnected.

Bob was now ready to cut the compressor loose. Btu Buddy said, “Look at this diagram before you open the system and let’s plan all of the moves ahead of time (Figure 2). Notice that the only permanent suction line is between the ‘four-way valve’ and the compressor. Also notice there is a suction line accumulator in this line. Many suction line accumulators have a small hole drilled in the piping that must remain open (Figure 3). The purpose of this hole is to allow a very small amount of liquid refrigerant and oil to re-enter the suction line. We should place the suction line filter before the accumulator to protect it from foreign particles. As you can see, this creates a slight piping problem. It will require the filter to be offset with elbows because there is not enough room to just cut it in into the line. We want to get all of the piping ready to install the drier at the very last minute.”

Figure 3. This suction line accumulator has a small hole in the loop piping that allows a small amount of liquid refrigerant and oil to return to the compressor. This is the only way oil can return when it gets into the accumulator and it helps move any liquid refrigerant that may be in the accumulator to the compressor without risking liquid slugging. (Click on the image for an enlarged view.)

Btu Buddy said, “Examine the suction and discharge lines internally and tell me what you see.”

Bob looked them over; he even took a clean white rag and wiped the inside of the lines. He said, “There is black oil in the discharge line, but the suction line is clean.”

Btu Buddy said, “It looks like the compressor burned while running so the contamination must have moved out the discharge line. The liquid line drier will get most of it and the suction line filter will protect the accumulator and compressor.”

Bob set the new compressor in place and started cutting the pipe to the correct length to install the filter. He reached for the filter and Btu Buddy said, “Let’s get the piping prepared to install the filter and I am going to show you something just before we open the filter to the atmosphere. Now cut the liquid line and get it ready for the filter-drier, but don’t open it yet.”

Bob got everything ready for the filters and then asked Btu Buddy what is next.

Btu Buddy said, “Install your gauges on the system gauge ports and connect the nitrogen cylinder.”

Bob did this and turned to Btu Buddy, who said, “Now purge nitrogen through the entire system at 100 psig.”

Bob turned the nitrogen up to 100 psig and let it purge though the system for about 10 seconds.

Figure 4. This liquid line filter-drier allows it to filter in either direction by means of check valves. If just a plain filter is used, it will filter in one direction and the particles will be cleaned from the filter when the direction changes. (Click on the image for an enlarged view.)

Bob set the nitrogen to barely flow into the system while he placed the liquid line drier in the line. He then connected the piping to the suction line filter.

Btu Buddy then said, “Disconnect the nitrogen cylinder and open the system to the atmosphere and use the torch to fasten all piping connections.”

Bob did all of the torch work and Btu Buddy said, “Now turn off the gauge manifold valves as quickly as you can. You have heated the piping and as it cools, the nitrogen inside the piping will cool and create a vacuum in the piping and pull atmosphere into the system.”

Btu Buddy then said, “You have put this system back together with nitrogen inside, which will keep down oxidation at the points where you used the torch. You have placed the filters and drier into the lines that were not contaminated with air and oxygen by being open to the atmosphere for more than a moment, so they will have the most capacity to do their work efficiently. It is time to put R-22 into the system up to about 10 psig and then use the nitrogen to pressure the entire system up to 150 psig and leak check all connections, including your gauge connections.”

Bob asked, “Why don’t we pressure the system up to 250 psig?”

Btu Buddy said, “You should only pressure the system up to the working pressure of the weakest link in the system. That would be the compressor housing. Remember, the compressor can pump several hundred pounds of pressure, but the compressor shell is a low side device. The discharge line that handles the high pressure goes from the compressor inside the shell through the discharge line to the outside of the shell in this reciprocating compressor. Most compressor shells have a 150 psig working pressure. It is safe not to exceed that pressure for the compressor shell.”

Bob leak checked the system, evacuated it to a deep vacuum, and charged it by measuring the charge into the system. He then started the system.

Btu Buddy then said, “It is nice and cold, so the system should get some good long running hours in, which is good. The refrigerant in the system is a great solvent. It will clean any residue from the burnout from the coils and piping and be deposited in the acid removing filter and filter-drier. There is plenty of filter capacity here so there is nothing to worry about. This system should give plenty of good service for many years. Oftentimes a technician will take shortcuts and some acid is left in the system that will eventually cause the system to fail again. This system was professionally cleaned to the best standards.”

Bob then said, “There is a lot to this work. It is very technical but every step has a logical reason. Thanks for giving me the best.”

Part 1, “Btu Buddy 48: Grounded Compressor Motor,” appeared in the March 19, 2007 issue of Extra Edition.

Publication date:04/23/2007