Btu Buddy and Bob met for lunch and Bob had a question about the last service call yesterday: “You said that we had some unfinished business about the service call yesterday, yet you said that the call was complete. What did you mean?” (See “Btu Buddy 56: A Smelly Gas Furnace,” Nov. 19, 2007 issue.)

Btu Buddy then explained, “You did a good job replacing the single-wall flue pipe with double-wall pipe on that horizontal gas furnace. Any time a vent passes through an unconditioned space, double-wall vent must be used for proper venting. You got the system up to code level. The thing you didn’t do is examine the chimney to see if it was good to vent into.”

Bob asked, “What do you mean by that? It was a chimney.”

Btu Buddy responded, “I looked at the chimney and it was good for venting. What I wanted you to do was examine it and tell me that it was good.”

Figure 1. The combustion gas has a lot of moisture in it. The moisture is slightly acid. When combined with the soot in an old chimney, there is enough acid to attack the mortar between the bricks and break it down. (Figures are from Practical Heating Technology by William Johnson, published by Thomson Delmar Learning.) (Click on the image for an enlarged view.)

Btu Buddy explained, “Some older chimneys are just masonry, brick, or concrete blocks with no lining. These chimneys will deteriorate over time and actually can fall over.”

“How in the world can that happen?” asked Bob.

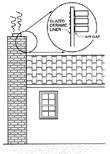

“These older chimneys were likely used for coal and wood and have a coating of soot from the past. These chimneys are very slow to warm up and there is a lot of condensate formed until they get hot,” said Btu Buddy. “This condensate, as we mentioned before, is slightly acid and will work with the old soot and actually eat the mortar out from between the brick (Figure 1). Chimneys that are being built today have a ceramic liner with a glaze on it much like the glaze on a coffee cup. If there is condensate, the glaze can take the mild acid. The liner is not completely against the brick, so there is a dead air space between the brick or block and the liner that acts as an insulator. Only the liner has to get hot for the flue gases to rise. You can back away from the house and see the liner protruding above the chimney when the chimney is lined. It is light brown or red (Figure 2).”

Figure 2. This chimney has a ceramic liner in it that will not deteriorate with moisture. There is an air space between the liner and the brick that acts as an insulator so the flue gets up to temperature faster. (Click on the image for an enlarged view.)

Btu Buddy answered, “There is oftentimes an alternative. Some chimneys can be lined with a stainless steel liner. It is worked down the chimney and connected to the flue from the furnace. This is not a simple installation. It is one for the experts that do this kind of work (Figure 3).”

Bob then said, “There sure is a lot to the venting system. It seems complicated.”

Btu Buddy remarked, “The National Fuel Gas Codes are used for venting practices and are available in the library, or your company probably has the books in the company library. You should check them out and read through them. There are a lot of illustrations to guide you. When you approach any job, you need to give the job an inspection to see that it meets the code specifications.”

Bob then asked, “Is there anything else that I should know about the job?”

Figure 3. This old chimney has no lining and the furnace is vented through a stainless steel liner that is worked down through the old chimney and connected to the furnace. (Click on the image for an enlarged view.)

Bob then said, “There is so much to remember.”

Btu Buddy said, “Yes, there is a lot to remember. The longer you are in the field, the more information that you gather. It is a good idea to always keep the safety of the customer in the forefront of your thinking. Protect the customer and it is hard to go wrong. You should always look at the safety aspects of any job and record any problems you see and let the customer sign the ticket. This could eliminate problems for you and your company if anything ever happens and you have documented it and made the customer aware of it.”

Figure 4. This vent sizing table came from the National Fuel Gas Code book and is used to size vent pipes. It takes into consideration the lateral (horizontal) vent matched to the vertical vent that terminates through the roof. (Click on the image for an enlarged view.)

Bob then asked, “Is there anything else?”

Btu Buddy said, “We have not talked about combustion air for the furnace. We will have to hold that for another day.”

Bob asked, “What is combustion air?”

Btu Buddy explained, “It is the air that must be provided for any furnace for combustion.”

Bob then said, “I just thought it used the air that was around the furnace.”

Btu Buddy said, “It is much more involved than that. Save that for next time.”

Bob then said, “Well, I guess I will have to. My brain is about full for now anyway.”

Publication date:12/17/2007