Bob was called to a new customer’s home that had a 5-ton heat pump. The home was a large ranch style home, all on one floor. The customer met Bob at the door and she explained to him that her power bills were considerably higher than the same months last year. Bob looked at the comparison and agreed. The seasons were similar, but the bills for this year were much higher.

Bob then went to the indoor air handler under the house and looked at the filter. All seemed normal with them.

He then went to the outside unit and looked around and nothing stood out to be a problem. He then went inside and checked the outlet temperature at one of the room registers. The temperature was 120°F. He then went to the room thermostat and checked the thermostat to see if the strip heat was calling for heat and it was not. He was looking confused when Btu Buddy appeared and asked, “What is the problem, Bob?”

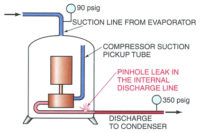

Figure 1. This electric heat element is grounded to the frame of the furnace causing it to produce heat all of the time. (From Practical Heating Technology by William Johnson, published by Delmar Cengage Learning.)

Btu Buddy said, “Check for amp draw at the strip heaters on both lines going to the heaters. Remember the time you had a strip heater that was grounded and it was drawing current all the time (Figure 1)?”

Bob got his ammeter from the truck and went under the house and checked all three strip heaters and there was no current flow. Bob then asked, “Now what?”

Btu Buddy then said, “You have ruled out heat from any source except the heat pump refrigerant cycle, so the excess heat must be coming from the heat pump coil itself. With an air discharge temperature like you are getting, I would suggest that you have a reduced airflow. A heat pump should not have a discharge temperature above about 105° and this one is running 120°. Feel the liquid line and tell me if it feels normal.”

Bob put his hand on the liquid line and exclaimed, “Boy, that line is really hot. Normally it would be about hand temperature, but that could burn you if you held it for long.”

“What does that tell you, Bob?” asked Btu Buddy.

“It tells me that the air stream is not taking the heat out of the refrigerant condenser coil, which is the indoor coil in the heat cycle,” said Bob.

Btu Buddy then asked, “What could be some reasons for these symptoms?”

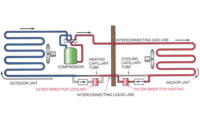

Figure 2. This illustration shows several places where airflow can be blocked in an air distribution system. (From Refrigeration & Air Conditioning Technology, 5th Edition, by William Whitman, William Johnson, and John Tomczyk, published by Delmar Cengage Learning.)

Btu Buddy then said, “Then you must eliminate those possibilities one at the time. It may be a combination of several of those things.”

Bob said, “I never thought of it being more than one thing. Most all of the trouble calls that I have worked on get back to one problem.”

Btu Buddy said, “That is usually the case. Let’s go do some checking. The simplest things to check would be the supply registers and return air grilles. I noticed that this house has multiple returns, so be sure to check them all.”

Bob went from room to room and checked the airflow possibilities and told Btu Buddy, “I found several rooms that both the supply and return fixtures were shut off. I talked to the homeowner and she said she was trying to save money by not heating those rooms. I explained to her that closing those fixtures was at least part of the problem.”

Btu Buddy said, “Now check the liquid line temperature.”

Bob held the liquid line and said, “That is much better. I think I will check the temperature with my thermistor temperature tester.”

After the check, Bob said, “The temperature is still 107°. I am not sure that we have gotten to the bottom of this problem.”

Btu Buddy then said, “Good point, check further.”

Bob looked at the fan wheel and commented, “The fan wheel has a lot of dirt in the curves of the wheel. I think I will clean the wheel.”

“Good point, Bob”, said Btu Buddy. “If the fan wheel is dirty, where did the dirt come from?”

Bob responded, “It had to come through the filters. At some point the filters must have been really dirty and let dirt pass.”

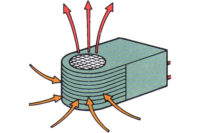

Btu Buddy then said, “Most filters only get the larger particles of dirt; much of the fine dirt slips through. In the summer, the coil is wet and acts as a super filter. I would suspect that the coil is dirty also.”

Bob got set up and cleaned the fan wheel and the coil, and said, “I can’t believe how much dirt came out of the core of that coil. It is a good thing I had this pressure washer. It just kept pushing out dirt. That especially made detergent for coils really did the trick.”

When Bob got the system back together, he started the unit up and after it had run for about 20 minutes, he looked at the temperature of the liquid line and said, “The temperature is down to 100°. That works for me.”

Btu Buddy suggested, “Bob, you need to check the outlet air temperature now that you have made these changes.”

Bob went in the house and checked the air temperature at the same place he had checked before and the temperature was 100°.

Bob went back outside with Btu Buddy and told him the results and Btu Buddy said, “Now you have confidence that you got to the complete bottom of the situation. Be sure and talk to the homeowner and tell her what you did. Be sure and mention the outlet air temperatures will be lower, but that the system will be more efficient.”

Bob asked, “Why didn’t you suggest that we put gauges on the system and check the pressures?”

Btu Buddy explained, “You could have connected your gauges. However, we came to the same conclusions without installing gauges. Remember, every time you fasten your gauges, you let out some refrigerant. The system has a critical charge and you may alter the charge when connecting the gauges. Also, you always have the possibility of leaving a leak behind and then you would be called back to the same job later to add refrigerant.”

Bob then said, “None of that would be good.”

Bob talked to the homeowner and explained everything to her and she understood to leave all airflows alone.

When riding away, Bob asked Btu Buddy why high head pressure resulted in such a dramatic change in power consumption in a heat pump and Btu Buddy said, “Let’s go to lunch and talk about it. Bring your text book so we can discuss some examples.”

Publication date:02/18/2008