The day had been very hot and Bob was really tired after spending all day on rooftops working on equipment when he received a call from the dispatcher telling him about a restaurant that was having difficulties. The restaurant expected a big crowd in the dining room that night and the air conditioning was off.

Figure 1. This capacitor tester can tell the actual capacitance of a capacitor. (Figures are from Refrigeration & Air Conditioning Technology, 5th Edition, by William Whitman, William Johnson, and John Tomczyk, published by Delmar Cengage Learning.)

When he got on the roof he noticed that the fan motor was turning, but seemed to be very slow. As he approached the condensing unit, the fan stopped. A few seconds later the compressor shut off because of high pressure.

Bob was sure that the fan capacitor must be the problem, so he turned off the power and removed the old capacitor and went down to the truck for a replacement.

While at the truck, he used his capacitor tester to check the capacitor (Figure 1). He was surprised that it checked out OK. He carried the new capacitor up to the unit anyway and installed it. He started the unit again and the fan was still turning slowly and ran for a few minutes and stopped again. He let the unit sit for a few minutes and placed his clamp-on ammeter on the condenser fan wire and started the unit again. The fan was supposed to draw 6 amps and it was drawing 7 amps. Now the picture was getting clear. Then Btu Buddy appeared and Bob explained what was happening.

Bob asked, “What could be wrong that would cause the motor to draw 7 amps? That is only slightly more than the 6 amps that it is rated at.”

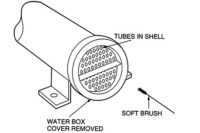

Figure 2. This illustration shows the two bearings that support a vertical condenser fan motor. (Click on the image for an enlarged view.)

Bob then asked, “What is the difference in the type of wear on a fan that blows out the side?”

Btu Buddy explained, “When a prop type fan is a side discharge, it has a small amount of thrust towards the back of the motor, but most of the wear is on the bottom of the bearing because the fan shaft is laying in the bearing. You might say that the shaft is cradled in the bearing.”

Bob then said, “It seems like that is the best bearing and fan combination. Why use top discharge fans?”

Figure 3. This illustration shows a side discharge air-cooled condensing unit. Notice that the hot air and the noise are discharged out the side of the unit. (Click on the image for an enlarged view.)

Btu Buddy then asked, “What are you going to do now?”

Bob said, “I have a night number for a supply house that is close to this job. I am going to call them and get a fan motor. The owner will have to pay an extra fee for night duty, but under the circumstances, I am sure that will be OK.”

As Bob was going down the ladder, the owner came around the building and Bob explained the situation. The owner said to go ahead because he really needed the dining room to be cool for this evening’s party in that dining room.

Bob met the supply house agent and purchased the fan motor and went back and installed it. The unit started up and ran just as it should. He went into the dining room and made sure the thermostat was set correctly and the owner said, “Thanks, Bob, this really saved the party. It is a party for a really good customer and it would be hard to explain why the air conditioning is not working. They will be here in about an hour and the dining room will be cool by then.”

As they were riding away, Btu Buddy said, “Well, Bob, you now have another very satisfied customer for yourself and your company. Good loyal customers are not easy to get and your company will notice this. It is not easy to work these service calls after-hours and after a hard workday, but you are in the emergency service business. Other peoples’ problems are your income.”

Bob said, “Boy, this has really been a long, hot, and tiring day, but very rewarding.”

Publication date:07/20/2009