The dispatcher called Bob with an urgent service call from the city’s convention center. A convention was going on and the air conditioner was off, and it would re-start but only run a short time and shut off again. The maintenance man said that he had to reset the high pressure control to get it started. Exhibitors and attendees at the convention were getting unhappy. This was a new commercial customer and Bob was anxious to make a good impression.

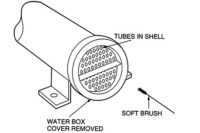

Figure 1. This chiller has two compressors. (Figures are from Refrigeration & Air Conditioning Technology, 5th Edition, by William Whitman, William Johnson, and John Tomczyk, published by Delmar Cengage Learning.) (©Delmar Cengage Learning.) (Click on the image for an enlarged view.)

Bob entered equipment room and found that the unit had permanent gauges to observe high, low, and oil pressures. He just had to open the valves to the gauges to read them. The unit was off.

Bob asked the maintenance man how long the unit would run and he said, “About 15 minutes, then it sounded like it was straining and shut off.”

Bob reset the high pressure control. The unit had been off for awhile so the system had a tower, condenser, and piping full of cool water. The system started up and sounded good. In a few minutes, the head pressure began to climb. Then things happened fast. The head pressure continued to rise and he could see that the unit was going to shut off again, so he shut it down.

Bob was looking bewildered when Btu Buddy appeared and asked, “What seems to be the trouble, Bob?”

Bob said, “It is happening too fast for me to think. I wonder if those gauges and the high pressure control are in calibration?”

Btu Buddy said, “I bet they are. Those controls are very reliable. Here is what I want you to do. Let the system stay off until the condenser water has cooled. The condenser water pump will continue to run and cool the water. Then I want you to start it again. I want you to feel the refrigerant liquid line while it is running and tell me what you feel. You want to also watch the condenser water temperature, both in and out.”

Bob gave the water another five minutes to cool down. He observed the water returning from the water tower and it was 80°F. The water leaving the condenser and returning to the tower was the same.

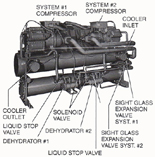

Figure 2. Notice that the condenser water is coming to the condenser at 85°F and returning to the tower at 90° when it should be returning at 95°. The condenser is not removing the heat from the refrigerant. (©Delmar Cengage Learning.) (Click on the image for an enlarged view.)

Bob then said, “The compressors are beginning to complain. I am going to shut it off.”

Btu Buddy asked, “Did you draw any conclusions from that exercise?”

Bob said, “I believe that the liquid line was too warm, but I didn’t have a thermometer on it. The condenser water only had a 5° rise and it should be about 10°.”

“What do you think, Bob?” asked Btu Buddy.

“I think that the condenser is not taking the heat out of the refrigerant like it should. The liquid line should not get that warm. The water-cooled condenser should condense the refrigerant at about 105° and there should be about 10° of subcooling, which means the liquid line should be about 95°. That is slightly above hand temperature and it was uncomfortably warm,” said Bob.

Btu Buddy said, “Then what is the problem?”

Bob said, “The condenser is dirty and must be cleaned before we are going to get this system to work.”

Btu Buddy then said, “That is great. You are telling me what the problem is, not the other way around. What are you going to do next?”

Figure 3. This machine has a motorized rotating brush and a water line to keep the brush lubricated and wash the residue away. You can do very quick work with this setup. (©Delmar Cengage Learning.) (Click on the image for an enlarged view.)

Bob went to management and explained the situation and that he could really hurry up the repair. They said go ahead.

Bob called in and got the shop moving. Meanwhile, he valved off the condenser and drained it down. He then removed the heads to expose the tubes. The maintenance man said, “They look clean.”

Bob said, “Take this small pen flashlight and look closely. Can you see the actual copper that the tubes are made of?”

He looked and said, “No, it seems to have a coating on it. How could that be? I keep the water tower clean.”

Bob then said, “There are several things that you have to do to keep the condenser operating at high efficiency. My helper and the equipment will be here in a few minutes. Stay with us and I will explain the steps to you.”

Btu Buddy then said, “That is great. Don’t hide information, share it. It will come back to you in a good way.”

To be continued in the July 19, 2010 issue.

Publication date:06/21/2010