Mounting Square Ceiling Diffusers

The most important thing to know about surface mounting square ceiling diffusers is that it normally requires additional framing to which the units will be secured. The location of the diffusers must be determined and framing installed prior to the sheet rock or ceiling surface installation. We often receive calls for mounting instructions after the sheet rock has been installed, which is too late to provide framing without removing the installed surface.

Framing requirements will vary, but there are some general guidelines that we use. Installing screws in the face of a diffuser will work as it does for grilles, but the duct return flanges behind diffuser edges are generally not available to provide a secure mounting base for screws. Also, many surface mount frames do not have a flat surface nor is there a screw hole fastening option available.

Furthermore, screw fastening certainly does not enhance the aesthetics of the installed diffuser. While it is acceptable for a low wall return grille to have a few screws in the border frame to hold it in place, a diffuser in plain view in a ceiling is subject to scrutiny. If the unit is not supplied with screw holes, running a few screws into it will certainly detract from the finished look and may cause a rejection on the final punch list.

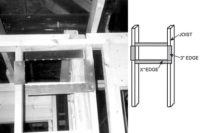

All sheet rock is mounted to ceiling joists. Joists are usually parallel to each other and spaced at two to three feet apart, depending on local building codes. In most cases, the framing for the diffuser can be mounted to the top of, and perpendicular to, the joists. Screws are then used to mount the back pan to the framing. Framing members should be centered on the diffuser location to allow sufficient clearance for the diffuser inlet and associated duct. (See Figure 1.)

Additional care must be taken to avoid any protrusions or features that will occupy the space necessary for the framing on the rear side of the diffuser. Framing should also be at a depth that will allow the diffuser to firmly set against the sheet rock. Most diffuser back pan heights are less than the depth of the joist. The sheet rock or ceiling surface is installed into an opening provided for the diffuser.

The diffuser core should be removed prior to installation to allow for screws to be installed in the top of the back pan transition; this is the flat portion on the rear of the back pan. Screws are then used to secure the back pan to the framing. It is helpful to use washers to prevent the screw heads from being driven through the back pan if the framing is not flush to the ear of the pan. In most cases, the screws can be placed in a manner to not be visible from the occupied space after the diffuser core or face is reinstalled.

After Sheet Rock Installation

Now let’s return to the question that often arises as to how to surface mount a diffuser once the sheet rock has been installed without framing behind it to which the diffuser back pan can be secured. In these cases, the use of a surface mount frame specially sized to fit the overall dimension of the diffuser will solve this dilemma.

The surface mount frame is a device that is installed in a cutout made between the ceiling joists. These devices are readily available from Titus and other manufacturers.

The surface mount frame is secured by sandwiching the sheet rock between the back of the frame and brackets supplied with the frame or fabricated onsite. It replicates a standard ceiling grid module to provide mounting identical to that of a lay-in frame diffuser. (See Figure 2.)

Once the surface mount frame is installed, the diffuser can then be laid in the frame just as it would be in a suspended grid ceiling. The surface mount frame does add a border to the finished appearance of the diffuser, but it does so without screw holes so it still has a clean appearance. An upside to using a surface mount frame with a lay-in diffuser is that by simply pushing the diffuser up and out of the opening, a convenient access port to the space above the ceiling is available.

While the surface mount frame does represent some additional diffuser costs, the reduced labor requirement, elimination of cross work among trades, and the flexibility of the installation sequence offer a distinct advantage.

There are several methods of surface mounting grilles, registers, and diffusers that vary in the amount of preparation, cost, and appearance. Since the correct surface mounting method can make or break the finished appearance of any installation job, proper planning and good product knowledge are the keys to selecting the appropriate method for any given product and application.

Publication date: 04/16/2012