Now, Bob’s company has promoted him to help train a new employee, right out of a school specializing in HVAC, just like Bob was. Bob is now Tim’s Btu Buddy. Tim is anxious to travel with Bob. Tim realizes that he is right out of school, with the theory and lab work that he accomplished in school, but still needs help. He knows that he worked with many of the components of the systems in the school, under ideal conditions with good light and air conditioning. Now it is into the field, sometimes under the house with poor lighting, or out on the rooftop in the sun, where the real action is. He is naturally and normally reluctant, but he has Bob to help guide him.

Bob and Tim were on their way to a “no cooling” call at a commercial building location. When they arrived, the manager said, “The unit was running and cooling when I opened the building this morning, and all of a sudden, I noticed that it was getting warm. The thermostat is set at 72°F and the store temperature is 78° now. I can’t imagine what has happened.”

Bob and Tim went first to the thermostat and noticed that the indoor fan was running, but there was no cool air coming out of the air registers.

Bob asked Tim, “What do you think we should do next?”

Tim said, “You are giving me a chance to solve this. Thanks. Let’s go to the condensing unit and see what is going on outside.”

They had to place a ladder up the side of the building and go to the roof. They found that the unit was not running.

Tim suggested, “Let’s remove the control panel door and see if the thermostat is sending a signal up here to the contactor coil.”

They found that there was no signal coming to the roof and Tim suggested, “Maybe the thermostat is defective. There is no power to the compressor contactor coil. Let’s go and jump it out and see if the condensing unit starts up. If it does, that will tell us that the thermostat is defective. Changing the thermostat is a simple matter.”

They removed the thermostat cover to reveal the connections in the sub-base. The thermostat was typical and used the R terminal as the hot terminal and the Y terminal as the cooling or compressor terminal. They jumped from the R terminal to the Y terminal, which should start the compressor if the thermostat is defective. Tim went to the roof and found that the unit was not running. He checked the power at the compressor contactor and there still was no power.

When Tim reported to Bob that there was still no power at the contactor, Bob said, “I am going to turn the unit off at the thermostat and jump these circuits out one at a time and see what I find.”

Bob turned the thermostat to the off position and jumped from R to G and they heard the fan start. The jumped from R to W and they heard the furnace start up. He jumped from R to Y and they heard the indoor fan start.

Tim asked, “What in the world is keeping the condensing unit from starting? When the indoor fan starts, they are supposed to start together.”

Bob responded, “There must be something in the wiring. Think of the system:

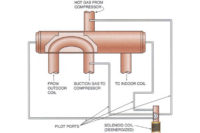

1. The power source for the control wiring is in the air handler (Figure 1). It is the junction for all of the control wiring.

2. The R wire is routed to the thermostat sub-base. It distributes the power back to the fan relay in the air handler on the G terminal and the Y wire back to the air handler with the Y terminal and on to the condensing unit.

Our problem is in the Y wire somewhere, because the other two circuits are working. Let’s go to the air handler.”

They went to the attic and found the air handler, and Bob said, “I see the problem from here. Do you see it?”

Tim looked and said, “I don’t see it. Give me a clue.”

Bob said, “Follow the R wire as it leaves the air handler to the thermostat. Then follow the Y wire as it returns to the air handler. Then follow the Y wire as it leaves the air handler to go to the condensing unit.”

Tim took a few minutes to follow these circuits and said, “The Y wire comes back to the air handler and when it leaves the air handler, it drops down to a float switch in the secondary drain pan. Oh, the drain pan is full. The float switch is keeping the condenser from starting and making more water in the drain pan, which would overflow and run down on the ceiling and then on down to the conditioned space. It is just doing its job.”

“Great,” said Bob, “you have the picture. Not only do we have to unstop the primary drain pan, but we have to clean out the secondary drain pan. Let’s start with the secondary drain pan and get the system running. It should be easy because as you can see, it is full of insulation.”

Tim raked the insulation out of the secondary drain pan and the pan drained. The switch closed and the condensing unit started.

Tim said, “That simple little float switch prevented a ceiling repair down below. What a great idea. Why does the secondary drain pan drain line go off toward the parking lot instead of going to the back of the building where the other drain line goes?”

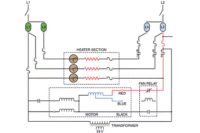

Bob said, “Look at this diagram of a residential system (Figures 2 and 3). The secondary drain line goes out the end of the house where it would be noticed. The owners should be told that if they ever see water dripping out that fitting, they should call for service. That is their second line of defense against water in the ceiling.”

After they cleaned the secondary drain pan, they used the shop vacuum to clean the primary drain line by going to the end of the line and sucking the sludge out of the line. This is much preferred to blowing the line backwards from the end of the line to the air handler which would push the obstruction back to the unit pan. They then placed an algaecide tablet in the drain pan to retard more algae growth.

They informed the building manager what they found and presented him with a bill for the service call.

Publication date: 10/22/2012