Now, Bob’s company has promoted him to help train a new employee, right out of a school specializing in HVAC, just like Bob was. Bob is now Tim’s Btu Buddy. Tim is anxious to travel with Bob. Tim realizes that he is right out of school, with the theory and lab work that he accomplished in school, but still needs help. He knows that he worked with many of the components of the systems in the school, under ideal conditions with good light and air conditioning. Now it is into the field, sometimes under the house with poor lighting, or out on the rooftop in the sun, where the real action is. He is naturally and normally reluctant, but he has Bob to help guide him.

Bob and Tim were on their way to a “low heat” call at a residence when the dispatcher called them back and told them that the homeowner had called and explained that the furnace was hot, but the home was cold. The dispatcher had told the owner to shut the furnace off until Bob and Tim arrived. Bob said, “That was a good idea. There was probably no danger because of all of the safety devices on all heating equipment.”

Tim asked, “Do safety devices ever fail to protect the owner?”

Bob said, “When a control manufacturer designs a safety device, like a high limit control, a motor over temperature control, or a low pressure safety control, they put the control through thousands of duty cycles to prove the control is reliable before they go into manufacturing the control. The manufacturer also tries to make them fail-safe. For example, a high pressure control should always fail to open the contacts in order to stop the equipment if it is over-stressed.”

When they arrived, they talked to the customer and she said, “The furnace comes on from time to time, but the house is cold.”

Bob told Tim to turn on the furnace and they would observe its operation. The gas furnace started normally and in a few minutes, the fan started as it should, so they continued to watch to see what happened. The furnace was blowing hot air and everything was looking good when all of a sudden the furnace shut down, but the fan kept blowing.

Tim said, “The thermostat is set at 72°F, but the house temperature is 63°. I don’t get what is happening. Why is the furnace heat source shutting down?”

Bob said, “Either we have a weak high limit switch or the furnace is overheating. The key to the problem is, the heat source is shutting down before the thermostat is satisfied.”

Tim asked, “How do we tell which one is the cause?”

Bob said, “Get the temperature tester and let’s measure the air temperature rise across the furnace.”

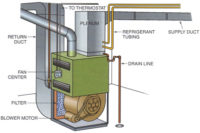

They placed a temperature lead in the return air and one in the duct leaving the furnace (Figure 1).

Bob said, “Look on the furnace nameplate and see what the allowable temperature rise is for this furnace.”

Tim looked and said, “A 40° to 70° rise is what it says. What does that mean?”

Bob explained, “Let’s only look at the maximum rise for now. That is 70°. If the return air temperature is 63° + 70° maximum temperature rise, the maximum air temperature should be 133°. What is it?”

Tim said, “It is 160°. Now what is the problem?”

Bob said, “The temperature rise across any furnace tells us the amount of airflow, providing there is a good heat exchange. We now know that there is either not enough airflow or the heat exchanger is not transferring enough heat to the air for some reason. Soot is a common cause if the flame is smoking. Soot will build up in the heat exchanger and act as an insulator. All heat exchangers must have the heat removed as it is heated, or they will overheat.”

Time said, “This problem is getting deeper and deeper. What is next?”

Bob responded, “This is a gas furnace; they are not likely to smoke. Let’s look at the inside of the heat exchanger with a mirror and see what the flame looks like.”

Tim said, “The flame is nice and blue, as it should be. When I use the flash light and mirror, the heat exchanger looks clean; no soot is visible. So I guess there is not enough airflow. What do we look for next?”

Bob said, “Let’s go first examine the furnace filter. This house has no regular service contract with our company. We have no idea what kind of condition the air side of the system is in.”

As they examined the system, Tim said, “The air filter is very dirty and I changed it.”

Bob now said, “With that much dirt in the air filter, I bet the squirrel cage fan blades (Figure 2) are dirty and the cooling coil is probably dirty. What you can always bet on is if the fan blades are dirty from air that passes through the filters, the cooling coil is dirty. The cooling coil is wet in the summer and is a natural filter of small particles that slip through the air filter.”

They cleaned the fan blades and the coil and started the furnace again and checked the air temperature rise across the furnace. It was still too much and Bob said, “I think there are some air registers blocked. Let’s go and see.”

They went through the house and found there were 12 air discharge registers and five of them were closed to keep from heating unused rooms.

Bob said, “Probably the owner could close three registers without causing a problem, but we have to open at least two of the closed registers to keep from having problems.”

They opened two registers and the air temperature rise was 65°.

Bob said, “That looks much better. The system will now heat the house without shutting off because of high limit and we have 5° for the filter to get dirty without having a problem.”

Tim said, “This business gets bigger and bigger all of the time. You really don’t need a college degree to become good in this field; you get all you need in technical school.”

Bob said, “I make a great income, comparable to a four-year college degree, with my technical college education. And a great thing about this career is that you can keep on learning and expanding your knowledge and advancement forever.”

Tim said, “That is a point well taken.”

Publication date: 2/19/2013