Now, Bob’s company has promoted him to help train a new employee, right out of a school specializing in HVAC, just like Bob was. Bob is now Tim’s Btu Buddy. Tim is anxious to travel with Bob. Tim realizes that he is right out of school, with the theory and lab work that he accomplished in school, but still needs help. He knows that he worked with many of the components of the systems in the school, under ideal conditions with good light and air conditioning. Now it is into the field, sometimes under the house with poor lighting, or out on the rooftop in the sun, where the real action is. He is naturally and normally reluctant, but he has Bob to help guide him.

Bob and Tim were in the company conference room where Bob is set to give Tim some extra training at Tim’s suggestion.

Bob said, “Tim, you asked for more explanation of what superheat is. This is not a very simple topic. It will take a couple of meetings to go into detail about:

1. What it is.

2. Why it is important.

3. How it is used.

4. How it is monitored.

“It’s important for any air conditioning or refrigeration technician to have a good practical understanding of these topics because we have to use them every day.”

Tim said, “Thanks for taking the extra time to get me well grounded in these topics.”

Bob said, “We will cover superheat and in more sessions we will discuss subcooling, an equally important topic.

“Let’s take a look at water, a substance that everyone has some familiarity with. Water is a refrigerant just like R-22 or R-410A. It just operates at different pressures and temperatures. Most people know that water boils at 212°F. What most people don’t know about water is that it boils at 212° only at standard conditions — a barometric pressure of 29.92 in. Hg (Figure 1). If you change the barometric pressure, you change the boiling temperature. For example, if you take a pan of water high in the mountains, the barometric pressure is less, because the column of air above it is not as high, so the water will boil at a lower temperature. Air is matter; it has weight and takes up space, the definition of matter. The weight of the air above is what creates atmospheric pressure. When the water boils up on the mountain, it boils at a lower temperature because it is at a lower pressure (Figure 2).

“A very important point: The boiling temperature of a liquid can be controlled by controlling the pressure above the liquid. Once you understand that statement, you can better understand what the evaporator portion of the refrigeration system is all about.”

Tim said, “Keep going. I think I am keeping up with you up to this point.”

Bob then explained, “Since water boils at a lower temperature up on the mountain, it is very hard to cook certain foods. Beans and potatoes don’t get up to the required temperature. Your grandmother solved this problem with a pressure cooker. By increasing the pressure in the pan with a lock-on lid, she could raise the boiling temperature by containing the steam on top. She typically raised the pressure to about 15 psig above atmospheric pressure and the beans would cook while at high altitude up on the mountain. Pressure cookers are also used at sea level to elevate the temperature and shorten the cooking time.

“This boiling temperature that we are talking about is also known as saturation temperature. The saturation temperature for water at standard conditions is 212°. It is called saturation temperature because at standard conditions, 29.92 in. Hg, the water is saturated with heat; you cannot heat water above 212°. If you add more heat, the water will just boil faster.

“While water is boiling, it is changing its state from a liquid to a vapor. Heat it more and you just make more vapor, or steam.

“Another very important fact: The steam that is leaving the water is saturated with heat. If you add more heat to it, it will be superheat. Heat that is higher than the saturated temperature is superheat.

“If you take any heat out of the steam above the water, it will condense back into water and fall back into the pan.”

“That is a good explanation of boiling of water and turning it to steam. How does it apply to air conditioning?” asked Tim.

Bob said, “The evaporator in a refrigeration system is just like a pot of water on the stove. The only difference is the air conditioning evaporator (or refrigeration evaporator) is like the pressure cooker, except at different temperatures and pressures. The liquid refrigerant boils and changes to a vapor and the vapor is superheated to a temperature of about 10° above the boiling or saturation temperature. Actually, water can be used as a refrigerant in an air conditioning system but it is hard to work with.

“The design temperature for an air conditioning system evaporator is 40°. When you reduce the pressure low enough on a container of water, it will boil at 40°. The reason water is not used as a refrigerant is because the amount of vapor generated is so large that a compressor is not feasible.

“Modern refrigerants do not require large piston or chamber displacements because they do not have to boil large volumes of vapor.”

“The pieces are beginning to come together. I have heard all of this in class, but applying it is another matter,” said Tim.

Bob then said, “Let’s get back to using water as an example for a refrigerant. If you reduce the vapor pressure above the water to .248 in. Hg of vacuum, the water will boil at 40°, the actual design temperature for an air conditioning coil (Figure 3). This would work, but the vacuum pump would have to be enormous. And operating a system at those low vacuums would require that it be perfectly leak-free. These design conditions prevent water from being used in the compression type of refrigeration. Water is used in another type of system, called an absorption system. You will probably never be called on to service one of these.”

Tim said, “Yes, let’s stick to what we will see in the field.”

Bob continued, “Up to now, we have only been talking about boiling or evaporating the refrigerant. After the refrigerant is boiled to a vapor, the vapor has to be removed by a pump, a vapor pump. That is what the compressor is. The vapor is removed in the suction line to the compressor. A compressor is a vapor-only pump. It takes the vapor and compresses it to a very small volume and pushes it into the condenser. When we say that a compressor is a vapor pump that is exactly what we mean. It will not tolerate liquid. If liquid gets into the cylinder of a piston compressor, it will not compress. The piston may push some liquid through the discharge valve, but the liquid will scrub the lubrication from surfaces that need to be lubricated. If the compressor cannot push the liquid through the valves, it will stall, and break the valves, shaft, piston or rod. The one thing it will not do is compress. Some compressors are more tolerant to liquid, such as the scroll or rotary compressors.”

“Wow, I didn’t realize it was that serious,” said Tim.

Bob said, “Once the vapor is removed from the evaporator, we must be sure that it is vapor, not liquid. Remember, the liquid refrigerant will have a saturation temperature corresponding to the pressure. In a typical evaporator that is made into a coil of tubing, when the liquid all boils to a vapor, the vapor temperature will be saturated with heat at the same temperature as the liquid refrigerant. In simple terms, suppose the boiling saturation temperature is 40°; the vapor rising off of the liquid will be 40°. Remember it is saturated with heat; if we remove any heat, it will turn back to a liquid. If we raise the temperature, the vapor will take on heat, called superheat. When the vapor is superheated, there is no liquid present.

“There are two things that superheat tells the manufacturer, and the manufacturer expects the service personnel to understand these two things:

1. Superheat proves the efficiency of the coil. The manufacturers’ designers want the coil to be as full of liquid refrigerant as possible because it is a more efficient heat exchange.

2. The correct superheat reading assures protection of the compressor from liquid damage.

“Most manufacturers use 10° (+ or - 2°) of superheat, or somewhere between 8° and 12° superheat. We have to be able to accurately take superheat readings to know how a coil is performing and that the compressor is protected. It is vital that we learn how to take superheat readings.”

Tim said, “That was a long explanation. Let’s see how it is done in the field.”

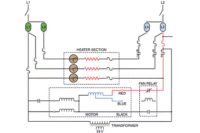

Bob said, “The most accurate way to measure superheat is to take the pressure reading and the temperature reading at the same location. You really want to know what the pressure and temperature readings are at the coil outlet (Figure 4), but you usually do not have a pressure port at the evaporator, so you may take the temperature and pressure at the suction line at the condensing unit and make some assumptions (Figure 5).”

Tim said, “That was a big lesson. When can we apply it to a system?”

Bob said, “We will go to a service call in the field and do some superheat measurements next.”

(Continued next month.)

For Part 2 of this series, go to Btu Buddy 125: Superheat Explained - Part 2.

Publication date: 7/22/2013

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!