Bob is a service technician who is well trained and nationally certified. However, he has sometimes suffered from the same confusion that all technicians occasionally do — the facts that he gathers may or may not point to the obvious cause of the problem or the best solution. But Bob has had something that no one else has. He recalled his long-time HVACR mentor and imagines him accompanying him as “Btu Buddy,” someone who reminded him to take time to stop and think before rushing to judgment, helping keep him on the right track, even with facts that are confusing.

Now, Bob’s company has promoted him to help train a new employee, right out of a school specializing in HVAC, just like Bob was. Bob is now Tim’s Btu Buddy. Tim is anxious to travel with Bob. Tim realizes that he is right out of school, with the theory and lab work that he accomplished in school, but still needs help. He knows that he worked with many of the components of the systems in the school, under ideal conditions with good light and air conditioning. Now it is into the field, sometimes under the house with poor lighting, or out on the rooftop in the sun, where the real action is. He is naturally and normally reluctant, but he has Bob to help guide him.

Bob and Tim were on their way to a no cooling call. The spring season was still cool at night and warm in the daytime. The customer told the dispatcher, “The unit started up at about 10:30 a.m. this morning and made a noise, but did not cool the house, even though it is still running.”

They arrived at the home and talked to the customer who said, “The unit has not shut off, but it is still not cooling. Feel the air at the air outlet in the hall.”

Bob held his hand in the air stream and said, “The air is just room temperature. What kind of noise did the unit make and where did the sound come from?”

The customer said, “The outdoor unit made the noise. It is located outside my office window. I work from my home and was sitting at my desk when I heard the noise.”

Bob then said, “The fan is probably the noise maker. We will check it out.”

Bob and Tim walked around the house to the condensing unit in the back.

Tim put his hand in the discharge air stream of the condenser and said, “This air seems to be the same temperature as the air that is entering the unit. It is not removing any heat from the house. I will get the gauges and tools and we can see what is going on. I don’t believe the compressor is running.”

Tim returned with the tools and removed the compressor access door and said, “The compressor is not running.”

Bob said, “See if the compressor is warm.”

Tim touched the compressor and said, “It is very slightly warm.”

Bob asked, “How does the discharge line feel?”

Tim said, “The unit is still calling for cooling, the fan is running, but the compressor is not hot and the discharge and suction lines are about the same temperature. The compressor is not running.”

Bob then said, “See if there is voltage to the compressor leads.”

Tim checked the voltage and said, “Yes, there is voltage. The internal overload must be tripped. I am going to shut the system down and do an ohm test to see if the compressor overload has tripped (Figure 1).”

Tim did an ohm test on the compressor and the readings were:

• Run to Common - 4 ohms

• Common to Start - 30 ohms

• Run to Start - 34 ohms

Then he said, “The compressor windings seem to be like they should. I checked the common to ground and the meter showed infinity. This looks like it should run.”

Bob said, “Start the unit up and do an amperage test of the compressor while it is running.”

Tim started the unit and then clamped his ammeter around the common wire and said, “It seems to be pulling about ½ amp, if I can read the meter at that low of a reading.”

Bob then said, “Turn the unit off and let the five minute timer time out.”

Tim shut the unit off and they oiled the fan while waiting for the timer to time out.

Tim asked, “Would you remind me why there is a five minute timer?”

Bob explained, “It is not good for motors to start up without a waiting period for the windings to cool down. Remember, a motor pulls about five times the run amperage on start up. Sometimes an operator will turn the thermostat up and down several times while adjusting it. The compressor motor will not start but one time until it has a cool down period. After the cool down period, it will start. This is also a good feature after a power failure. Think of the apartment house system we worked on last week. It had 250 apartments. When the power is restored after an outage, all 250 units would try to start up the compressor at one time, not to mention all of the refrigerators, fans, and lighting. That would be a huge power surge. All of the timers on the condenser units would not time on at the same time, so the power surge would be much less.”

Tim then asked, “What is next?”

Bob said, “We are going to take advantage of the power surge on the compressor to see if it is really running. With the ammeter on the common terminal, watch the ammeter when the unit is started. The ammeter is only measuring the current to the compressor.”

Tim and Bob were watching the ammeter when Bob started the unit.

Tim said, “Sure enough, the meter needle just wiggled and rose very little and dropped back to near zero.”

Bob said, “That motor is running, but it has no load. It is a reciprocating compressor. The crankshaft must be broken and the only thing that is turning is the motor rotor. It would pull very little current.”

Tim said, “I guess that means the compressor needs changing.”

Bob said, “Yes, the compressor will have to be changed. But the question is: Why did the crankshaft break? Was it a compressor internal problem or a system problem?”

Tim said, “How would we tell the difference?”

Bob said, “This is an R-22 unit and it has a crankcase heater. Do an ohm check on the heater.”

Tim checked the crankcase heater with the ohmmeter and said, “Sure enough, it has an open circuit. How did you know to check the heater?”

Bob said, “It was pretty obvious from the description the customer gave us about the noise that something physical happened out here at the condensing unit. We suspected it was the fan, but when we started and stopped the unit, the fan made no noise.

“The compressor was running, but we discovered that it was not pulling any load. It was apparent that the physical damage must have been to the compressor, and at the time of startup. That pointed to liquid or oil slugging at startup.

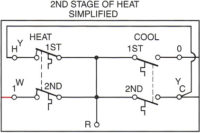

“R-22 has an affinity or attraction for oil. It will migrate to the crankcase during the off cycle. Last night was cool outside and warm in the house, a natural time for any refrigerant that was in the low pressure side of the system to migrate to the compressor crankcase (Figure 2 and 3). When the unit started up this morning, the compressor pulled in refrigerant and probably oil when it boiled because it was full of liquid refrigerant, into the cylinders. We know that the one thing that would not happen is a cylinder full of liquid that would compress. The force broke the crankshaft,” said Bob.

“Now, let’s get set up to change the compressor and the crankcase heater.”

Tim said, “If we just changed the compressor, this would happen again. We should always check the crankcase heater even on routine checkups.”

“That is correct, Tim. You can usually tell by gently touching the heater. Don’t try to press your finger on it or you will get burned.”

Tim said, “Another day and another learning experience. It is great that it goes on and on. It’s never boring.”

Publication date: 5/19/2014

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!