Bob is a service technician who is well trained and nationally certified. However, he has sometimes suffered from the same confusion that all technicians occasionally do — the facts that he gathers may or may not point to the obvious cause of the problem or the best solution. But Bob has had something that no one else has. He recalled his long-time HVACR mentor and imagines him accompanying him as “Btu Buddy,” someone who reminded him to take time to stop and think before rushing to judgment, helping keep him on the right track, even with facts that are confusing.

Now, Bob’s company has promoted him to help train a new employee, right out of a school specializing in HVAC, just like Bob was. Bob is now Tim’s Btu Buddy. Tim is anxious to travel with Bob. Tim realizes that he is right out of school, with the theory and lab work that he accomplished in school, but still needs help. He knows that he worked with many of the components of the systems in the school, under ideal conditions with good light and air conditioning. Now it is into the field, sometimes under the house with poor lighting, or out on the rooftop in the sun, where the real action is. He is naturally and normally reluctant, but he has Bob to help guide him.

Bob and Tim were at the shop after a day of service calls. The weather was still hot, 93°F, and Bob said, “We just did a service call with a system that was overcharged and had an orifice expansion device. I would like to go into further details with you on a system with a thermostatic expansion valve (TXV) for an expansion device. The season is getting late and there won’t be many more near design days with the temperature in the 90s. Let’s use the unit in the shop and do some training on it. Are you willing to stay after work for a while?”

Tim said, “Yes, it is a chance to learn even if it is after hours.”

They got the gauges and fastened them to the R-22 unit. The suction pressure was 68 psig and the head pressure was 275 psig, and Tim said, “Those readings are about right for the conditions.”

Bob said, “Yes they are. Now what we want to do is fasten the temperature lead on the suction line at the outdoor unit. The suction line is only about 10 feet long because the air handler is just inside the shop on the floor in a closet. The superheat should be about 12° to 15°. Now connect a lead to the liquid line for measuring the subcooling and let’s see what the readings are.”

Tim said, “Here are the readings. The suction pressure is 68 psig, 40° evaporator temperature, and the suction line temperature is 55°. The superheat is 15° (55 - 40 = 15). The head pressure is 275 psig, about 125° condensing temperature, and the liquid line temperature is 110°. The subcooling is 15° (125 - 110 = 15). That looks good to me.”

Bob said, “Yes, that is about perfect and here is what it tells us:

1. The evaporator has a full charge of refrigerant in it and is performing at about design expectations.

2. The condenser has a full charge of refrigerant and it is performing correctly.

“If we add some refrigerant to the system, what is going to happen to those readings?”

Tim said, “More refrigerant will cause the head pressure to rise for sure.”

Bob said, “Fine, add about a ½ pound of refrigerant, using the scales.”

Tim added some refrigerant and they waited a few minutes and took more readings. Tim said, “The head pressure went up and the suction pressure went up as expected.”

Bob asked, “What are the readings?”

Tim said, “The suction pressure is 75 psig, 44° evaporator temperature, and the suction line temperature is 59°. The superheat is 15° (59 - 44 = 15). The head pressure is 316 psig, 135° condensing temperature, and the liquid line temperature is 110°. The subcooling is 25° (135 - 110 = 25). The superheat is the same, but the head pressure went way up and the subcooling went up.”

Bob said, “This is a 5 ton unit. A ½ pound too much refrigerant didn’t make a huge difference, but look at the evaporator temperature, 44°, that will make a big difference in capacity. It will lose capacity and will not cool as well, and it will not remove humidity as well. It may not be noticeable to the occupants, but the run time will be longer and the power bill will be more. The compressor is working under more pressure, so the amperage will rise. Where do you think the excess refrigerant is located?”

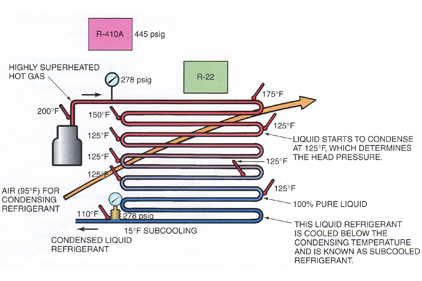

|

| Figure 1. This is an example of a condenser operating at design conditions for a typical standard air conditioner. (From Refrigeration & Air Conditioning Technology, 7th Edition, by William Whitman, William Johnson, John Tomczyk and Eugene Silberstein published by Delmar Cengage Learning.) (©Delmar Cengage Learning.) |

Tim said, “It appears to be in the condenser because of the extra subcooling.”

Bob said, “That is correct. Notice that a lot of the excess refrigerant was located in the evaporator in the system that used the orifice metering device because the superheat was 0 and the compressor was flooded with refrigerant.”

Tim said, “Yeah, that is right, now that you mention it. That was a very different system from the TXV. What is the key to charging the TXV system?”

Bob said, “You must check the superheat to be sure that the TXV is performing correctly. The real key is how much refrigerant is in the condenser. In any system without a receiver, you must make sure that the correct refrigerant level is in the evaporator and the condenser under near design conditions. The subcooling circuit serves as the receiver. We were lucky that the weather is close to design conditions of 95° outside, the perfect temperature for outdoor conditions. Measuring inside design conditions involves taking the ambient air temperature, dry bulb, and determining the humidity with the indoor wet bulb temperature. The conditions here at the shop are about 75° dry bulb and about 50 percent humidity. It is too much trouble to narrow them down exactly, so we are assuming that they are close enough. The system pressures seem to line up well enough for our tests.”

Tim asked, “Now what?”

Bob said, “Connect the recovery unit and remove about 1 pound of refrigerant.”

Tim removed about a pound of refrigerant and waited a few minutes for the pressures to settle down. He said, “The superheat is still 15° but the pressures and temperatures have dropped. The suction pressure is 64 pounds, or 37° evaporator temperature with a suction line temperature of 52° (superheat 52 - 37 = 15). That seems like it would provide more cooling because of the cooler coil.”

Bob explained, “The coil is cooler, but the quality of the liquid is not as good entering the expansion valve. It may be partially vapor which has almost no value in the change of state process.”

Tim said, “Wait a minute, how did the change of state get into the subject?”

Bob explained, “The most heat exchange takes place when the liquid is boiled to a vapor. When vapor from the condenser slips through the expansion valve it costs capacity. Pure liquid must be furnished to the expansion valve. When that liquid is subcooled, even more capacity is gained at the evaporator. How about the condenser readings?”

Tim said, “All readings have come down. The head pressure is down to 243 psig for a condensing temperature of 115° and the liquid line temperature is 115°. The subcooling is 0° (115 - 115 = 0). I see what you mean. If we removed more refrigerant, the condition would get worse. Would the superheat ever rise?”

Bob said, “Yes, if any more refrigerant were removed, there would not enough for the expansion valve and the superheat would start to rise. Go ahead and add ½ pound of refrigerant back to the system and get it back to normal.”

Tim resumed the system to normal operation and disconnected the gauges and instruments and said, “There is nothing like seeing it in action for a great lesson. I hope I got all of that.”

Bob said, “That was a valuable lesson that all technicians should take the time to perform. These things take time to learn and it is hard to take time to find a system and experiment on it. All systems do not act exactly the same. This was a TXV system with no receiver for extra refrigerant; the subcooling circuit is the receiver in this system. Larger systems with receivers will not always perform like this one.”

Publication date: 10/20/2014

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!