Mention the combination of heat pumps and hydronics and it’s likely the discussion will quickly turn toward geothermal water-to-water heat pump installations. While, it’s true, geothermal heat pumps do offer excellent opportunities in combination with low-temperature hydronic distribution systems, they are not the only viable way to combine the heat-leveraging ability of heat pumps with the unsurpassed comfort offered by modern hydronic distribution systems.

The biggest challenge associated with most closed-loop geothermal heat pump installations is getting sufficient piping into the ground. Most residential and light commercial buildings don’t have sufficient land area for the extensive excavation required to install horizontal earth loops. This often limits the choice to boreholes and vertical loop installations. Although such earth loops are proven technology, even in cold northern climates, the installation cost and site disruption can be substantial.

In our area, I currently estimate a vertical earth-loop installation at about $3,500 per ton of heating capacity, based on recent quotations from drillers. The installation of vertical loops requires specialized equipment (drilling rigs) and procedures (such as grouting the tubing within boreholes). Most HVAC contractors and plumbers are not equipped to provide this part of the installation.

Vertical earth-loop installation requires knowledge and proper procedures to protect ground water from potential contamination. Some municipalities now mandate that all vertical borehole installations be done by certified well drillers and in conformance with all ground water protection regulations. I suspect this will become increasingly common as the geothermal heat pump market expands.

In retrofit installations, both horizontal and vertical loop installations can be highly disruptive to existing landscaping, pavements, etc. Putting all this “disruption” back in place after installing the earth loop piping takes time and money, which should always be factored into the installation cost. By the way, it’s not a good idea to spread out the “tailings” that come from drilling deep holes in the earth, throw some grass seed on it and expect it will quickly turn into a nice lawn.

These observations are not meant to dissuade you from installing closed-loop geothermal heat pumps, but to encourage you to think beyond the often over-simplified consumer graphics showing piping neatly placed under silky-smooth grass and crack-free pavements.

Above Ground

Air-to-water heat pumps extract low-temperature heat from outdoor air and deliver it to a stream of water. That water can distribute the heat throughout buildings, just as heat provided from a geothermal water-to-water heat pump. In many areas of the U.S., air-to-water heat pumps can attain coefficients of performance (COP) that closely rival those of geothermal heat pump systems. Even in cases where they can’t quite equal geothermal heat pump COPs, the extra cost of installing an earth loop is often hard to justify based on annual electrical savings associated with higher COPs.

I recently ran an estimated cost comparison for both types of systems supplying a house with a 36,000-Btuh design load in Syracuse, New York. The seasonal average COP of the geothermal heat pump was estimated — using software from a geothermal heat pump manufacturer — at 3.28. The seasonal average COP of the air-to-water system was estimated — using software from an air-to-water heat pump manufacturer — at 2.8.

I’m sure most of you aren’t surprised the geothermal heat pump came in with the higher COP. But, your electrical bill is not based on COP, it’s based on the kWh used. For the example house in Syracuse, the difference in annual operating cost, based on electricity at 13 cents per kWh, was $98. The installed cost premium for the geothermal heat pump over the air-to-water heat pump was $3,785. This included the subsidy currently provided by the 30 percent residential renewable energy federal tax credit on the geothermal heat pump installation, but not available for the air-to-water heat pump system.

Would you spend an extra $3,785 to save $98 per year?

Opportunity Versus Status Quo

Air-to-water heat pumps are extensively used in Europe and Asia. The 2012 global air-to-water heat pump market increased 5.4 percent over 2011 to 1.37 million units, according to the August 2013 issue of the Japanese publication JARN. It estimated the European market for air-to-water heat pumps was about 181,000 units in 2012. In China, the air-to-water heat pump market increased 11 percent over 2011 to 699,000 units. Interestingly, JARN also reports U.S. sales during this period at about 1,000 units.

A bit of online research shows all the large heat pump manufacturers — such as Mitsubishi, Fujitsu, Panasonic, and several others — offer residential-scale air-to-water heat pumps in markets other than North America. Over here, most of these companies compete with each other selling ductless mini-split heat pump systems. I can only assume most of them look at the North American market as dominated by forced-air distribution (which is true) and are not convinced air-to-water heat pumps would gain sufficient traction to justify bringing these products to our market.

I recently came across a company named ThermAtlantic Energy Products, located in St. John’s, Newfoundland, Canada. Benoit Maneckjee, president and chief of product development at ThermAtlantic, has recognized a unique approach for combining air-source heat pumps and hydronics.

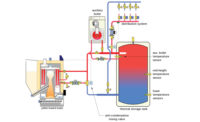

He observed that many air-source heat pump condenser units are readily available on the North American market. What is missing is a way to marry those condenser units to a well-thought-out “balance of system” using modern hydronics technologies. Maneckjee filled that gap by developing the DX2W (direct expansion to water) module. Figure 1 shows this unit (the white cabinet) installed with other system components.

The DX2W module is the hub and control center for several subsystems, including the outdoor condenser, buffer tank, auxiliary electric boiler, low-temperature hydronic distribution system, and even a chilled water air handler

for cooling.

In its primary heating mode, the outdoor unit serves as the evaporator for the refrigeration system. Hot refrigerant gas passes through the coaxial condenser within the DX2W module, transferring heat to water. This water is circulated to a nearby buffer tank using the module’s internal circulator. The temperature of the buffer tank is regulated based on outdoor reset control. This maximizes the thermal performance of the heat pump by not raising the buffer tank temperature above what is needed for the current space-heating load.

The buffer tank prevents the heat pump refrigeration system from short-cycling when supplying a highly zoned hydronic distribution system operating under partial-load conditions.

Upon a demand for space heating, heated water from the buffer tank passes through the motorized three-way mixing valve and on to a distribution system using low-temperature hydronic heat emitters, such as radiant panels. On its way to these heat emitters, the heated water passes through an electric boiler, which also is controlled based on outdoor reset. This boiler provides supplemental heating, if needed, on very cold days. Water returning from the distribution system passes back into the buffer tank. This mode of operation is shown in Figure 2.

If the heat pump is not operational, or is operating in defrost mode, the full space-heating load is provided by the electric boiler. The three-way valve within the DX2W unit simply provides a U-turn for flow driven by the distribution circulator(s).

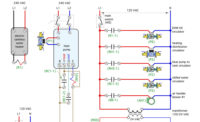

In cooling mode, the heat pump operates to chill water in the buffer tank. When there is a demand for cooling, some chilled water from the tank is routed through the coil of an air handler to provide a portion of the sensible cooling load and the entire latent cooling load (e.g., moisture removal). Additional chilled water from the buffer tank enters the three-way mixing valve, where its temperature is adjusted based on the current dew point of the interior air. The temperature of the water leaving the mixing valve remains slightly higher than the current interior dew point temperature.

This prevents surface condensation when this water is routed through the radiant panel distribution system to provide radiant cooling. Figure 3 shows the system in cooling mode.

Another unique aspect of this product is its control system. Maneckjee’s background in control system design allowed him to create a complete microprocessor-based system that coordinates operation of all the peripherals connected to the DX2W unit. The real-time operating status of the unit, including temperatures, power demand, and even net system COP, are calculated and displayed on an Internet page, as shown in Figure 4.

The controls also capture the operating history of the unit and can send email alerts based on detected failure modes or poor performance conditions. The ability to monitor performance over the Internet can save technicians time and money while helping to ensure the unit is operating as expected.

Show Me the Numbers

In space-heating mode, the COP of the DX2W system varies from approximately 2.1 at 0°F outdoor temperature to 4.6 at 60° outdoor temperature. Computer modeling for a 5-ton heat pump supplying a house with a 50,000-Btuh design load in a Canadian maritime climate, such as Nova Scotia, shows an average seasonal COP of about 3.4. This is based on a low-temperature distribution system operating with a supply water temperature of 110° under design load. As with all heat pump systems, a distribution system that can provide design-load output at a supply water temperature of 120? (or lower, when possible) is crucial for good performance.

Many current-generation air-to-water heat pumps, such as the DX2W, use R-410A refrigerant and are best applied in climates where outdoor design temperatures are 0° or higher. However, future developments in heat pump technology are likely to extend this ambient air temperature range downward by at least 10°.

The upper end of the water temperature range also is likely to be extended, which will further expand possibilities for retrofitting high-temperature air-to-water heat pumps into existing hydronic distribution systems. For situations where outdoor temperatures occasionally drop below 0°, it’s relatively easy and cost-effective to integrate an auxiliary energy source into the system to meet peak loads, as well as to serve as a backup heat source. The ThermAtlantic system uses an electric boiler, controlled based on outdoor reset, for this purpose.

As those of you who’ve read my past columns know, I seldom go into detail about specific products. I would rather discuss design principles and best-practice applications of generic hardware. Still, when a really well-thought-out product comes along that demonstrates what’s possible with modern hydronics technology, I want others to know about it and explain to them why it makes sense for our market. And, for the record: I have no commercial or professional involvement with ThermAtlantic Energy Products.

The system level approach the DX2W unit is designed around is a great example of what’s possible using modern hydronics technology in combination with standard refrigeration hardware (e.g., heat pump condenser units). It’s also proof that air-to-water heat pump systems are viable in many parts of North America, including locations well north of the Mason-Dixon Line.

The electrically based renewable infrastructure in North America is growing rapidly. New wind farms and utility-scale solar PV installations come online every month. It seems inevitable that electrically driven heat pumps will become the premier method of completing the “consumer end” of this renewable energy supply system.

Air-to-water heat pumps should be part of this future. I certainly hope air-to-water heat pump offerings in North America will expand from numbers currently too small to show on a bar chart alongside those from European and Asian markets. There’s a great opportunity at hand for those who can listen beyond the current green buzzwords, think beyond air-side distribution, and plan beyond Dec. 31, 2016, when the residential renewal energy tax credits expire. And, as is true in the biblical story of David and Goliath, don’t assume that the big guy always wins.

Publication date: 4/27/2015

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!