Bob is a service technician who is well trained and nationally certified. However, he has sometimes suffered from the same confusion that all technicians occasionally do — the facts that he gathers may or may not point to the obvious cause of the problem or the best solution. But Bob has had something that no one else has. He recalled his long-time HVACR mentor and imagines him accompanying him as “Btu Buddy,” someone who reminded him to take time to stop and think before rushing to judgment, helping keep him on the right track, even with facts that are confusing.

Now, Bob’s company has promoted him to help train a new employee, right out of a school specializing in HVAC, just like Bob was. Bob is now Tim’s Btu Buddy. Tim is anxious to travel with Bob. Tim realizes that he is right out of school, with the theory and lab work that he accomplished in school, but still needs help. He knows that he worked with many of the components of the systems in the school, under ideal conditions with good light and air conditioning. Now it is into the field, sometimes under the house with poor lighting, or out on the rooftop in the sun, where the real action is. He is naturally and normally reluctant, but he has Bob to help guide him.

Bob and Tim were on a job where one of the other technicians had been having a hard time with a persistent leak. He thought the leak was somewhere in the indoor unit, but he could not pinpoint it.

They went in to talk to the customer about the problem and the customer said, “The unit will run a few days and then freeze up. Then we do what the other technician told us to do; we turn the thermostat to ‘fan on’ and the system to ‘off’ for 30 minutes and then switch back to ‘fan off’ and the system to ‘cool.’ The unit will cool for several hours and we have to do it again.”

Bob asked, “Do you change your own filters?”

The homeowner said, “Yes, we change it once a month and keep up with it on the calendar. We changed it last week.”

Bob said, “There has obviously been a leak. An air conditioning unit should never operate cold enough to freeze the coil. The unit is running now. We are going to look into it.”

They went to the condensing unit out beside the house and Tim said, “There is ice on the suction line now.”

Bob said, “Turn off the disconnect and let the indoor fan keep running. The thermostat is calling for cooling. Then put some gauges on the unit.”

When Tim got the gauges on the unit, they went inside and checked the filter and coil to see if they were dirty. Tim said, “The filter is sucked inside the unit. What is that all about?”

Bob explained, “The filter is dirty, so dirty that the fan pulled it out of its frame. This may be our problem. Install a new filter and check the coil and fan blades and see if they are dirty.”

Tim checked them and said, “They are both clean. I can’t figure this out. Something unusual is going on.”

Bob said, “Let’s start the unit and see what the gauges read.”

They started the unit and let it run for a few minutes and Tim said, “The charge is low. The refrigerant is R-22 and look at the suction gauge. It is reading 41 psig; that corresponds to 18°F. No wonder it is freezing.”

Bob said, “Let’s go in and talk to the owner a minute.”

They went in and Bob asked the owner to show where they changed the filter and she went to the central hall and pointed to a central air filter.

Bob said, “Well, that answers one question. There was a filter in the air handler under the house. It came shipped with the unit and should have been removed when the system was installed. There is no need for two filters and that one got overlooked and it got loaded up to the point that it pulled out of the frame. There was no harm done. I still believe you have a leak somewhere. We are going out to find it.”

Tim asked, “What are we going to do?”

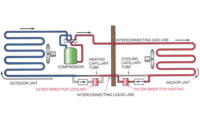

Bob said, “There has been a lot of time spent on this unit trying to find the leak. I think that we should recover the refrigerant down into a vacuum to get all of the refrigerant out of the oil in the system. Then bring the pressure back to about 2 psig with nitrogen. Then we will cut the suction and liquid line at the condensing unit. Cap all four lines with a cap with ¼-inch gauge connectors. We now have the system divided into two separate systems. Then we will put a small amount of R-22 in each system and pressurize each system to be able to run the electronic leak detector and find the leak.”

Tim then asked, “How much pressure should we put into the system?”

Bob said, “Read the label; it says the test pressures are 150 psig low and 300 high (Figure 1.) You will need an explanation. The low side is of course the evaporator section. For practical purposes, we will count the piping as the low side. In reality, the liquid line is the high side, but we will only need to pressurize it to 150 psig. The high side is in reality from the compressor discharge valve in the cylinder to the liquid line valve where we cut the line loose. The compressor suction line up to the low side suction valve on the cylinder is low side pressure rated. Strange as it may seem, most of the compressor is considered the low pressure side of the system. This is because the compressor itself is actually an enclosed high pressure device inside a low pressure shell. The point to really remember is that the compressor shell is the weak link in the system. If it is over-pressurized, it will separate and blow. That would be a mess and dangerous to anything surrounding it.”

Tim said, “Wow, how can we remember all of that?”

Bob said, “We can boil it down to make it simple:

1. Pressurize the low side (piping and evaporator coil) with a little R-22 and nitrogen up to 150 psig and mark it on the gauge.

2. Pressurize the condensing unit with a little R-22 to 150 psig and mark it on the gauge.

3. Let it stand under these pressures while leak testing with the electronic detector. If we find no leak and the pressure drops, we have a leak for sure.”

“Now let’s do it.”

They ran the detector over both systems and seemed to get a small leak somewhere inside the evaporator coil, but they could not find it. Finally Bob said, “Let’s take the evaporator coil out.”

They cut the piping at the evaporator coil and removed the coil out to the driveway and Bob then said, “Connect the gauge lines to the coil and pressurize it to 150 psig.”

They filled a large tub that they had in the truck with water and pushed the pressurized coil down in the water. It was leaking in multiple places.

Bob said, “This coil has too many very small leaks to be repaired. Go to the supply house and get another coil. Take a picture of the nameplate with your phone. Meanwhile I am going to show the customer this coil leaking so that they will understand. I will also get the piping connected back and make sure the condensing unit is good to go. When you get back, we should be able to set the coil, connect the piping, leak check the joints that we did, evacuate the unit, and start it up. We have a liquid line drier in the truck that we will install at the last minute.”

Bob showed the owner the leaks in the coil and explained, “I could probably push the fins back and repair these leaks. But there is something fundamentally wrong with this coil that likely happened during manufacturing. If I repaired all of these leaks, it would surely begin to leak somewhere else. Replacement is really the only good option.”

Bob then connected the suction and liquid line back to the condensing unit and about that time Tim arrived with the new coil. They set the coil and soldered it in place. Then, they cut in the filter drier in the liquid line.

Bob said, “Add a little R-22 for a trace refrigerant and leak check the four connections that we did. When I pulled the plugs out of the new coil, there was still nitrogen in the coil, proving that it was leak free.”

They leak checked the connections and found no leaks. Tim said, “I am going to connect the vacuum pump and turn it on.”

After the vacuum was down to 500 microns and they let the vacuum hold for 15 minutes, they broke the vacuum with R-22 and evacuated it down again to 500 microns and it was time to add the charge and start the unit.

Bob said, “Turn the refrigerant cylinder upside down and add liquid into the liquid line until it nearly stops flowing. That will be most of the charge. You are charging into the liquid line and liquid is going both ways, towards the expansion device and towards the condenser. You won’t be taking a chance on doing damage to the compressor. When the liquid flow slows down, turn the cylinder over and get ready to charge vapor into the system. It is 93° so we will charge the system like a design day of 95° to a condensing temperature of 125° or a head pressure of 280 psig. We should have a superheat at the condensing unit of about 12°.”

Tim got the temperature tester set up. The system had an orifice metering device so the superheat method was a good choice. When the charge was balanced out, they disconnected the gauges and temperature tester and told the owner that all should be good with the system.

They were driving back to the shop and Tim said, “We made a quick but good fix and the customer was happy to get the system back on and reliable. We showed him where the problem was.”

Bob said, “You will have happy customers when you do a good job and keep the customer informed. Just think about if it was you. Treat them like you would like to be treated. I bet your grandmother said that.”

Publication date: 9/21/2015

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!