Bob is a service technician who is well trained and nationally certified. However, he has sometimes suffered from the same confusion that all technicians occasionally do — the facts that he gathers may or may not point to the obvious cause of the problem or the best solution. But Bob has had something that no one else has. He recalled his long-time HVACR mentor and imagines him accompanying him as “Btu Buddy,” someone who reminded him to take time to stop and think before rushing to judgment, helping keep him on the right track, even with facts that are confusing.

Now, Bob’s company has promoted him to help train a new employee, right out of a school specializing in HVAC, just like Bob was. Bob is now Tim’s Btu Buddy. Tim is anxious to travel with Bob. Tim realizes that he is right out of school, with the theory and lab work that he accomplished in school, but still needs help. He knows that he worked with many of the components of the systems in the school, under ideal conditions with good light and air conditioning. Now it is into the field, sometimes under the house with poor lighting, or out on the rooftop in the sun, where the real action is. He is naturally and normally reluctant, but he has Bob to help guide him.

Bob and Tim were at a retail store and were preparing to do a routine service call on a 5-ton heat pump. It was a fall day with a temperature of about 50°F when they turned the heat pump on. The unit was heating well as they observed the system. They were inside the store at the air handler doing a visual inspection.

Bob said, “Let’s check the filters and put new ones in.” When they finished putting in the new filters, they oiled the fan motor and Tim said, “This fan wheel seems to be really dirty.”

They had the indoor unit back together and decided to move to the roof and give the outdoor unit a visual inspection. Tim had a cold soft drink in his hand and when he walked by the gas line a drop of water fell off of the soft drink can onto the discharge line and sizzled.

Tim said, “That discharge line sure is hot. Did you see that drop of water sizzle when it touched the discharge line? It must be over 212° because it boiled away almost immediately (Figure 1).”

Bob said, “We better check that out. That is not normal. The discharge line should never be over 212°. This system is running hot for some reason. You mentioned that the fan wheel was dirty. Let’s go down and see what the coil looks like. If the indoor coil is dirty during the heating cycle, it will cause excessively high head pressures and temperatures.”

They turned the system off, went back in, and removed the inspection panel to the indoor coil.

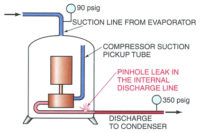

Bob said, “That coil is filthy. It looks like it’s dirty all the way through the core. If that’s the case I don’t know how in the world we can clean that coil in the unit (Figure 2). We are going to need to pump the refrigerant down into the outdoor unit in the cooling cycle and valve it off. Then we will recover what’s left of the refrigerant in the indoor coil. Then we will build the pressure up with nitrogen to atmospheric pressure so that we can disconnect the indoor coil.

“We will have to take the coil out of the cabinet and take it out in the parking lot behind the store and use the pressure washer to get this coil clean. I’m not sure what’s embedded in this coil but this is not normal. It seems to be totally impacted with something that looks like goo.”

They isolated the indoor coil and carried it outside where they capped off the piping lines and got set up to pressure wash it. They soaked the coil with a detergent compatible with aluminum and copper that the coil was made from. They used the pressure washer to get the coil clean all the way to the core. They had to be very careful to keep the pressure washer nozzle pointed straight into the fins so they would not bend them. The nozzle had to be kept at a distance from the fins so the full force of the washer would not impact the fins.

When they were through, some of the fins were bent so they used their fin comb to straighten them.

Bob said, “I have never seen a coil with that much stuff in it. I’m not sure what it is yet. We need to do an inquiry with the owner and see if he can help us figure out what was embedded in that coil. This unit is not all that old so it should not be that dirty inside. Goo just kept coming out of that coil as we washed it.”

When they were through with the coil, they carried it back inside and put it back in the cabinet and reconnected the piping. They then pressure checked the two connections at the coil where they had taken the coil out. These were the only two connections they had worked with so the system should be leak free now. They then connected the vacuum pump and pulled it into a deep vacuum down to 250 microns. The refrigerant was still valved off in the outdoor unit, so when they pulled the vacuum, they established that the coil wasn’t leaking. They were ready to open the valves and start the unit.

They started the unit and did a routine check on it checking pressures and temperatures and all seemed to be working well.

Bob and Tim then went and explained the coil situation to the owner. They told him that they had never seen a coil with so much dirt inside in the core of the coil that they had to take the coil out of the unit to the parking lot and clean it.

The owner said, “We had the store remodeled about two months ago and they did a lot of sheet rock work and there was a lot of dust in the air. They were told to turn off the air conditioner at that time while they were sanding and working, but I doubt that they turned it off because it was hot weather. We closed the store for a week while they did the remodeling and there was a lot of dust that we had to vacuum up after they left. I suspect that is where the large amount of dirt came from in the coil.”

Bob said, “Yes I’m sure that’s what it was. So many workmen do not understand what that amount of dust can do to a unit. This was during the cooling cycle so the coil would be wet while it’s running in cooling and a great filter for fine dust. That dust will travel through the air filter unless it’s a very high density filter and run straight into the coil and then the coil will become a filter with its wet surface.”

As they were riding away Tim asked, “Would you please review for me what happens when the indoor coil is as impacted as that coil was? What would be the result of long-term operation with the unit? I don’t understand why the owner didn’t notice a difference in the operation of the unit.”

Bob explained, “At the end of the cooling season the system would be operating marginally. It was not quite as hot during the end of the cooling season so it wouldn’t have been noticed as much. The same would happen at the beginning of the heating season. There would not be much call for heat so the system would be heating marginally. As the weather became colder, the unit would need longer running times to get the store warm. During these longer running times the unit would be operating at extremely high pressures and temperatures to the point that the compressor would probably shut down periodically on overload. If the system continued to operate like that without making a repair, it would eventually burn the compressor motor. The power bill would be excessive, but in a store they probably wouldn’t notice it. They would just keep paying the power bill. It’s a good thing for the owner that he called for a routine service check on the system. It was a good find on your part that you noticed how hot the system was running and that we checked it out and cured its problems.”

Tim then said, “It seems like the coil must have been really hot and would put out a lot of heat.”

Bob said, “Yes, the call for heat would put out extra warm air, but at the expense of operating with a high compression ratio for the compressor. The air volume would be greatly reduced. It was very hard on the compressor. High compression ratios equate to higher expense for each Btu of heat energy. When a compressor operates at high compression ratios like that one, the oil has a tendency to break down right in the top of the cylinder. We know that the temperature of the discharge line was more than boiling water’s 212°. It probably was 30° to 50° hotter in the top of the cylinder in the vicinity of the valves. The oil will break down and turn to carbon which will pollute the system and create acids. The best practice is to operate within the tolerances of the compressor’s design operating conditions.”

Tim said, “Another learning experience. We seem to have a different learning experience every day. That’s good. This is not a boring job.”

Publication date: 12/21/2015

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!