Bob is a service technician who is well trained and nationally certified. However, he has sometimes suffered from the same confusion that all technicians occasionally do — the facts that he gathers may or may not point to the obvious cause of the problem or the best solution. But Bob has had something that no one else has. He recalled his long-time HVACR mentor and imagines him accompanying him as “Btu Buddy,” someone who reminded him to take time to stop and think before rushing to judgment, helping keep him on the right track, even with facts that are confusing.

Now, Bob’s company has promoted him to help train a new employee, right out of a school specializing in HVAC, just like Bob was. Bob is now Tim’s Btu Buddy. Tim is anxious to travel with Bob. Tim realizes that he is right out of school, with the theory and lab work that he accomplished in school, but still needs help. He knows that he worked with many of the components of the systems in the school, under ideal conditions with good light and air conditioning. Now it is into the field, sometimes under the house with poor lighting, or out on the rooftop in the sun, where the real action is. He is naturally and normally reluctant, but he has Bob to help guide him.

Bob and Tim were at the house of a customer who said that her air conditioning unit did not cool well in the hot weather three days ago. She said the unit actually froze up and had ice on the outdoor portion of the unit on the big line. She shut the unit off and called for service. The temperature is 55°F today and they need to check the charge on the unit in very mild weather.

Bob and Tim explained that they were going to turn the unit on and check the refrigerant charge. Tim went to the thermostat and turned it down to 60° and they proceeded to the air handler to see what was going on at that point.

Tim said, “Look at the orifice metering device. It is frosting on the outlet side. That is not normal. We should never see frost on air conditioning unit piping.”

Bob said, “You are correct. That is wrong. We should never have frost on an air conditioning system line. It looks like a low charge. Let’s put the gauges on the unit and see what we see.”

Tim got the gauges and installed them on the R-22 system. The head pressure was running about 150 psi and the suction pressure was running about 40 psi.

Bob said, “The conditions in which we are trying to operate the system are not correct. It is 55° outside and this condensing unit should be operating in an atmosphere of at least 75° or 80°. The design temperature that this system was designed for is 95°. This is an R-22 unit and the head pressure should be running at about 275 psi. Get some plastic and let’s cover part of the condenser and see if we can get the head pressure up to design conditions.”

Tim got some plastic out of the truck and wrapped it around the condenser shutting off part of the airflow. He could only get the head pressure up to about 175 psi.

Bob then said, “This system is definitely low on refrigerant, but we should try to determine why it is low and find any leak before we add refrigerant. Turn off the system with the disconnect switch and get the electronic leak detector. We should give the system a visual check and look for oil stains as a place to start looking for a leak. We must always remember that oil is entrained in the refrigerant as it flows through the system and that anywhere there is a leak there should be a slight amount of oil residue.”

Tim got the electronic leak detector and they began examining the system for oil spots. They found a little bit of oil on a liquid line elbow entering the house. They started up the leak detector and determined “yes” that’s where it was leaking.

Bob said, “Get the recovery unit and let’s remove the refrigerant and repair this leak. Let’s go in and talk to the housewife about this. This leak looks as though it’s been there for quite a while and this is our first time to this job.”

They explained the situation to the housewife and she said, “We have had a lot of trouble with leaks through the years, and the service technicians have just been adding refrigerant each year. That is why I knew to look for ice on the big line out at the unit.”

Bob said, “Since you mentioned that this system has been plagued with leaks before, we are going to pressurize the system and do a thorough leak check from one end to the other. There may be more than one leak. We would like to settle this before we leave this job and get it leak free.”

The housewife said, “That is a great idea. We have been fooling with this leak now for several years and it’s time to repair it.”

Bob and Tim removed the refrigerant from the system and repaired the leak that they had found, then allowed a small amount of R-22 back into the system for a trace refrigerant and pressurized the system up to 150 psi with nitrogen. Then they each took an electronic leak detector and went over every inch of piping and all connections including in the coil and down in the condensing unit. They were satisfied that they had done as much as they could towards finding a leak. They connected the vacuum pump and pulled the system down to 250 µm and valved the vacuum pump off from the system and let it stand for a half-hour while they changed filters and oiled the motors. When they returned, the system was still holding the vacuum, so they were satisfied that they had all of the leaks repaired and got set up to charge the system in mild weather.

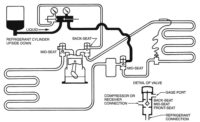

They allowed liquid refrigerant to flow into the liquid line service valve until it stopped flowing. Bob explained, “This should be very close to the complete charge for the system. We will wrap the condenser in plastic and start the system and see what the pressures are reading.”

They started the system and were able to get the head pressure up to 270 psi. Bob said, “This is the correct head pressure for a 95° design day. Now let’s check the superheat here at the condenser suction line and see what the superheat is (Figure 1 and 2).”

Tim checked the superheat and it showed 25° of superheat. He then said, “That superheat is too high. We don’t have enough refrigerant in the system.” So he started adding refrigerant and the head pressure started rising. He uncovered the condenser a bit and kept the head pressure at 275 psi. He continued to add refrigerant and kept the head pressure steady until he had 15° of superheat and 275 psi head pressure.

Bob said, “That’s as close as we can get to a perfect charge in this kind of weather.”

Tim said, “Yes, I think we have put a permanent fix on this job. Next spring when this unit starts up I will bet it still has the correct charge in it.”

Bob said, “Yes, that’s as good as we can do. Blocking the condenser to simulate a 95° day is a good way to get a very good charge into a system in mild weather.”

They then explained what they had done with the system to the housewife and she was pleased that the system had been checked out so thoroughly and thanked them.

Publication date: 5/23/2016

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!