Your role in this month’s troubleshooting situation is providing a second opinion on a failed compressor diagnosis. The customer’s complaint is that the unit isn’t cooling properly — the equipment is a heat pump package unit that is just past the warranty period for the compressor.

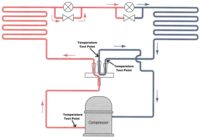

The technician asking you for a follow-up has limited experience with heat pump systems, and he explains that he arrived at the diagnosis that the compressor is not pumping based on the pressure readings found upon accessing the high and low sides of the system with a standard compound gauge set at the points shown in Figure 1.

The gauges showed a higher than normal suction pressure and a lower than normal head pressure.

When you arrive, you decide to use digital gauges to check the pressures, and what you find are the same readings that his gauges showed. You also confirm that this unit employs a fixed bore metering device and check valve system for both the indoor and outdoor coils. With the operating pressures established, you take the next steps of confirming temperature, eliminating the possibility of an air flow problem through either of the coils. You also access the manufacturer’s charging charts found on the interior of the service panel to determine what the superheat for this equipment should be in a specific situation.

When you conduct your evaluation, your finding is that the superheat is significantly lower than it should be.

Your troubleshooting question: Have you confirmed your colleague’s diagnosis, or have you determined that there is a different component that could be responsible for the poor performance of this system?

Compare your answer with ours here.

Publication date: 6/5/2017

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!