Bob and Tim arrive at the jobsite of a new customer. The customer is the owner of a shopping center that has a branch post office as one of its tenants. The complaint has been that the system is not controlling the indoor temperature in the postal facility.

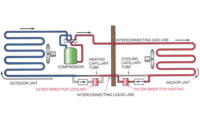

Tim tells Bob as they are arriving that the service ticket says that they are to service a 20 ton split system that uses a hot water coil for heating and an air conditioning coil and condensing unit for cooling. They are to do routine maintenance on the entire system.

They enter the building and are speaking to the manager of the post office and he explains, “this system has a problem about once a year due to a lot of paper dust in the air. The whole system has to be cleaned about once a year because the paper dust from handling the mail plugs up the entire air system to the air handler. We handle a lot of envelopes through our mail sorting machine and that creates a lot of dust and paper product in the air.”

Bob and Tim go to the air handler and examine it and sure enough the filter is stopped up with dust and it is only a typical hardware store type air filter that does not filter real well.(Figure 1) A lot of air goes through the filter that does not give up its fine dust. The Refrigerant coil becomes a good filter in the summer time because the coil is wet. Dust that passes through the filter is gathered on the wet coil fins. After looking the system over Bob suggests that they need to give the entire air handler a cleaning. He says, “we will need to use the pressure washer on the fan to get the dust out of the blower blades so I suggest we take the blower section outside behind the building and pressure wash it there. This is a pull-through fan system, so the fan is located in the airstream after the air is pulled through the filter the hot water coil and then the refrigeration coil. The fan coil is filthy with buildup of dust and all of this was pulled through the filter, the hot water coil and then into the fan wheel. The blower wheel is built up with dust so you know the filter the water coil and the refrigeration coil have to be really dirty. Let’s start by removing the blower wheel and taking it to the parking lot”.

They shut the system down and then turn off all power to the unit and remove the blower section to the parking lot and Bob said, “this gives us good access to the refrigeration coil for cleaning, but the water coil is before the air-conditioning coil so this is going to take a good soaking of detergent and then a lot of water flushed down both coils to get the dirt from between the fins of the coils. Get the chemical sprayer that has coil cleaner and let’s start applying it to both coils on both sides of the coils”.

They completely soaked the coil section with detergent that is approved for cleaning coils and while it was soaking in they moved to the blower section out in the back of the building. They sprayed the blower wheels with detergent and let them soak for a few minutes and then they took the pressure washer and cleaned the blower wheel.

Tim said, “I have never seen so much dirt in a blower”.

Bob said, “I have seen this before where a lot of paper was handled. There is a lot of dust or paper product in the air where paper is handled”.

They moved into the air handler and using a water hose and started washing the coils with large amounts of water using a spray nozzle. The equipment room had a drain in the floor very close to the air handler. As the water flushed out the bottom of the coil they used a squeegee to push the water into the drain. Tim said again, “look at the dirt. It just keeps coming out”.

Bob said, “let the coil drain for a few minutes until it stops dripping then give it another application of detergent making sure you get it thoroughly soaked to the core of the coils”.

While the coils were soaking they changed the filters in the filter rack. Then they oiled the bearings on the fan coil unit and motor. They looked at the belts and they were worn considerably so Bob suggested they change all three belts.

After the other maintenance had been done Bob said, “it’s time now to flush the coil again and see what we get out of it. If we get a lot more bad looking water out of it we may have to do another detergent soak and flush. We want to get it as clean as we possibly can”.

They flushed the two coils again and the flushing water looked good and clear coming out so they deemed that the coils were clean and they were ready to reassemble system. The blower section was now installed back into the cabinet and everything fastened together and they were ready to start up the system.

Bob said, “we have completely serviced the indoor portion of the system but we need to look over the condensing unit. Turn the power off and let’s examine the compressor contactor and check the fan capacitors to make sure they’re in good shape. This system has two fans for the outdoor unit so each one will have a capacitor”.

They examined the compressor contactor and determined that the contacts were really pitted and probably were not making a very good contact so they changed the contactor.

The outdoor coil looked good and clean so they didn’t bother to clean it.

They used their capacitor checker to check the capacitance of the outdoor fan motor capacitors and they were both good.

It was 65°F outside so they decided to start the unit up in in the air-conditioning mode and using the site glass determine if the unit had an adequate charge of refrigerant. So they started the system and the site glass filled up and looked good.

Then they changed the system to the heating mode and they found that hot water was circulating through the hot water coil so everything seemed to be working well.

Bob went to the manager of the postal facility and said, “I can get you a price on putting a high density filter rack in this air system which will remove this dust before it gets to the coils. This would eliminate this large service call every few months for cleaning the air handler”.

The manager said, “we don’t own the building, the building is owned by a corporation that owns the shopping center. This suggestion has been made in the past but the owners do not want to spend the money that it would take to modify the ductwork and put in a really high quality filter rack. They think it is more cost-effective to just clean the system a couple of times a year”.

Bob then said, “well there is something to be said for that because of the economics but it is hard on the equipment to go through this cleaning process. It is bound to affect the lifespan of the equipment but that is their decision to make”.

They put up their tools and as they were pulling away from the job Bob and Tim discussed what they had just done. Tim said, “that was a new experience. It seems like every day we see something different and that makes it interesting.”

Bob then said, “I know what you mean I’ve been doing this for several years now and every day is a new experience."

Publication date: 2/19/2018

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!