Bob and Tim are on their way to a spring start up for a chiller in an office building. It is a 100-ton water cooled reciprocating chiller with the chiller in the basement and the cooling tower on the roof. (Figure 1)

Tim had questions, “I have never worked on a chiller, really never have even looked at one and am not familiar with what we’re about to see”.

Bob said, “As far as the chiller itself is concerned the refrigeration circuit or cycle is exactly like the refrigeration cycle on a household refrigerator, a central air-conditioning system in a home, or any other reciprocating refrigeration system. They all have the same four components, compressor, condenser, metering device, and evaporator. A water cooled chiller like we’re going to look at is a little different because it has a water to refrigerant heat exchanger for the evaporator and the condenser has a water to refrigerant heat exchanger. For example, instead of having a fan blowing air over an open coil in a residential air-conditioning system the water cooled evaporator is enclosed in a shell and a pump circulates water over the evaporator coils. The chilled water then circulates up to the building to fan coil units (Figure 2) in each area. A fan coil unit has a fan and a coil in it with air blowing over the fins on the copper coil and distributing air to the conditioned space. The condenser is the same type, refrigerant to water heat exchanger in a shell.

The condenser uses a water pump to pump water through a shell that has a refrigerant to water heat exchanger inside it. The heat from the refrigerant is transferred from the coil into the water and the water is circulated to the roof and a cooling tower removes the heat from the water, it circulates the cooler water back to the condenser in the basement.” (Figure 3)

Tim then asked, “when you said “compression cycle refrigeration” what did you mean exactly”?

Bob explained, “Compression cycle refrigeration means any system that compresses refrigerant using a compressor. There are other types of refrigeration, such as the absorption refrigeration cycle. I will let you go home and research that one rather than explain it to you. This system that we are going to work on uses a 100 ton reciprocating compressor."

Bob and Tim arrive at the building and go to the basement where the chiller is located and Bob points out all of the points of interest on the refrigeration portion of the chiller. Then he explains what they should do next.

Bob said, “Since this is a water chiller and has two water circuits we will address the water circuits one at the time. The chilled water circuit is a closed loop and water circulates to every terminal fan coil in the building. We want to make sure that this loop is full of water before we try to start the chiller. At the control center we find there is a switch that allows us to operate the chilled water pump by pushing “on” at the control panel for the chilled water pump. The first thing we want to do is grease the chilled water pump and motor if there are grease fittings. Then we will start the chilled water pump and verify that we have chilled water flow.”

They lubricated the pump and the motor and were ready to start the chilled water pump. While they had their grease gun they lubricated the condenser water pump and motor also.

Bob said, “Push the chilled water pump “on” button and let’s verify chilled water flow”.

Tim pushed the button and the chilled water pump started and he looked surprised. Then he asked, “what do we do next”.

Bob said let’s look at the pressure gauges and check the pressure from one side of the evaporator to the other. I noticed that the gauges are reading 50 psi in and 40 psi out, that is a 10 psi difference which means water is flowing into the chiller barrel at 50 psi and out at 40 psi establishing that there is a 10 psi pressure drop across the chiller barrel, there is water flow."

Tim asked, “do we do the same with the condenser”?

Bob said, “No, since there is a cooling tower on the roof water flows to the outside, all of the water would have been drained from the system last fall. We will need to put the plug back in the drain line at the pump so that when we are on the roof we can fill the tower and piping from the cooling tower float assembly. The float assembly maintains a water level in the cooling tower just like a toilet tank maintains the water level in your toilet at home. We will need to go to the roof and look at the cooling tower and possibly clean it before we fill it with water, which will also fill the condenser in the basement”.

They went to the roof and looked at the cooling tower. They removed the inspection door where they could see the floor of the cooling tower and decided it was pretty dirty.

Bob said, “we have to clean this cooling tower basin and get all of this old dried algae out of the basin or the water will become fouled quickly. We need to go to the truck and get the water hose, rubber boots, the brush with a broom handle in it so we can brush the bottom of the tower, safety glasses, and facemask. We need to also bring the grease gun and lubricate the cooling tower fan bearings and the motor. The reason for all of the safety is because there is the possibility of very bad germs in this old algae. When we start scrubbing on it it’s going to create dust and it’s going to get in the air possibly in your eyes and possibly in your mouth. Not good”.

Bob and Tim gave the cooling tower a good cleaning and let the water drain out of the floor drain in the tower onto the roof where it would move on into the storm sewer from the roof drainage. They put the plug back in the bottom of the tower and were ready to fill the tower with water.

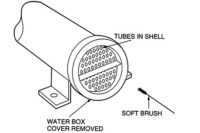

Bob said, “Open the valve that goes to the float mechanism to maintain water level in the tower. Also use the water hose that we have with us to fill the tower as quickly as we can. We also need to remind the building owner manager to call a water treatment company to treat this cooling tower water. Without treatment this system will be full of algae again. Algae will then start accumulating on the condenser tubes at the chiller which will act as an insulation and cause the head pressure to rise. When this happens the condenser will have to be cleaned by brushing the tubes inside the condenser. This is a lengthy service procedure."

While the tower was filling, they checked the belts on the fan motor at the cooling tower. They found the belts to be worn considerably so they changed the belts and rotated the fan so they would know it would turn freely. They had turned the disconnect switch to the fan motor off so that they could control it from the roof.

When the tower was full, they gathered up their tools and went back downstairs.

Bob said, “Push the “on” button to the cooling tower pump and let’s go back to the roof and see what the water flow looks like."

They went back to the roof and observed that the water was flowing over the top of the cooling tower and trickling down to the cooling tower media.

Tim then asked, “Why is the fan not running”?

Bob explained, “The fan only runs when the water is getting warm enough to cause the head pressure at the compressor rise. So the fan cycles on and off to maintain a water temperature in the basin of the tower at about 85°F. There is a thermostat mounted in that box hanging on the side of the cooling tower. Open the box and note the setting. Now turn the thermostat to a lower temperature and let’s see if the fan will start automatically."

Tim turned the thermostat down and the fan started running.

Bob then said, “Set the thermostat back to the original setting and the fan will stop. We now know that water is circulating correctly and that the fan will stop and start to control the water temperature. Let’s go back down to the chiller and examine it and get ready to start it operating."

They were now at the chiller and established that there was a 10 psi pressure drop across the condenser water shell. The chiller is ready to start, they put gauges on it to make sure that it has refrigerant.

Bob said, “Let’s check the contactor contacts before we start this chiller."

They pulled the disconnect to the chiller power circuit and opened the control panel door. They remove the cover to the compressor contactor and the contacts looked good. They put the cover back on the compressor contactor and closed the door to the control panel and turned the disconnect back on.

Tim said, “Those contacts really looked good."

Bob explained, “this chiller has the capacity to start up unloaded at low capacity and low amperage. The contacts will last much longer on this type of compressor startup. By starting up unloaded, it’s like starting a much smaller motor, then the motor loads up to full load. The contacts last much longer this way”.

Bob said, “Go to the control panel and set all of the switches to automatic. Remember they were set in the “on” position, set them to the “automatic” position so that the system will start up automatically."

Bob started the chiller by turning the “on” switch “on”. They observed the gauges. This was an R-22 chiller.

Bob explained, “This is a 100 ton chiller and it starts in the unloaded phase of operation, meaning that it has steps of loading. This particular chiller has 4 steps. It starts up at 25 percent loaded (25 tons), if the chilled water is not cold enough it will move quickly to 50% (50 tons), if that’s not cold enough it will move quickly to 75 percent (75 tons) and then on to 100 percent (100tons) full load operation”.

They could hear the compressor as it began to load up. It moved on up to 100 percent load and the chilled water leaving the chiller was 70°F. The chiller operated about 15 minutes and they heard it un load down to 75%. It operated about another 15 minutes and then unloaded down to 50%. As they observed the system and were cleaning up their tools the chiller then unloaded down to 25 percent of full load.

Bob said, “This system seems to be operating correctly. I think we’re through here."

Tim then asked, “We didn’t change any air filters?"

Bob explained to Tim, “The maintenance man in the building changes the terminal unit filters. So we have nothing to do with that, that is their responsibility."

Tim said as they were driving away, “Well that was a very different experience."

Publication date: 4/23/2018

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!