Compare the automotive industry of the 1980s with today’s industry, and you’ll find huge improvements in most every category. The same is true for the HVAC industry. Giant leaps have occurred in controls, application, and general efficiency.

Heat pumps of the 1980s were plagued with defrost control issues; reversing valve dependability; and, finally, mechanical control failure. Electronic board evolution, chip development, and refrigerant assisted reversing valves have made heat pumps as dependable as the standard air conditioner. But before you are convinced heat pumps can take over for HVAC in all markets, we need to investigate fundamentals.

Our first point is heat pumps, even the old ones, got a bad rap for when they worked as designed but the installation was substandard. Let’s take a step back and discuss the issues.

Back in the late 1980s and early 1990s, the government pushed for better efficiency, and heat pumps were targeted due to part-load winter efficiency. When weather is mild, it’s hard to beat the comfort and budget savings a heat pump provides over resistance heating. Electric bills were cut in half or more where heat pumps were installed in milder heating climates, like the south and southeast quarter of the nation. When nasty weather moved in, heat strips supplemented the heat pump to overcome the short-lived extremes.

Some of those 1990s installations were shot down almost immediately due to contractors simply changing a resistance heat air handler for a new heat pump system. The expectation of the owner was an electric heat pump would deliver heat the same as the old system. The contractor failed to explain how a heat pump works and failed to perform the work to lessen the impact different temperatures and climates may have on the heat pumps. Often, the contractor didn’t understand the new technology and purchased equipment without researching choices available.

Generally, we understand an air conditioner will produce air that has a difference, or delta, of approximately 20°F cooler than the air in the room. In the summertime, we take advantage of that air movement or draft due to the sensation we are cooler than the temperature indicates. Air moving across the skin gives the benefit of evaporation.

That same principle of a 20° delta in the summer means something totally different in the winter. If the temperature set point for winter is 68°, that 20° delta will provide air at 88° exiting the vent. If the vent is a conventional, three-way, stamped grille, 88° air is going to feel cold on 98° skin. The room is heating, but comfort suffers.

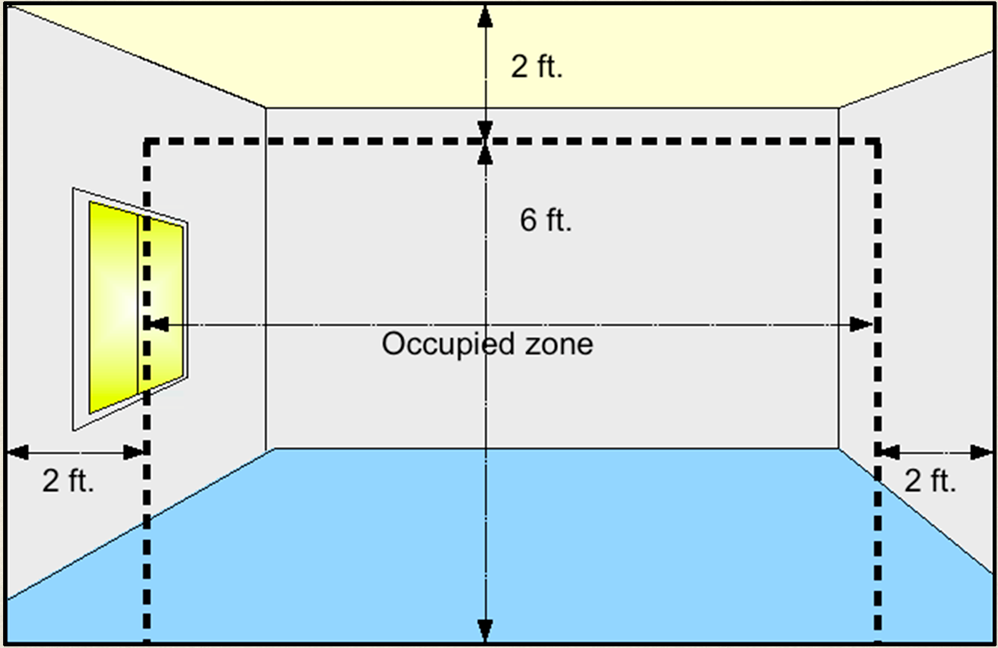

For well 30-plus years, manufacturers have provided information on grille performance and explained how to deliver air outside of the occupied zone. The occupied zone is a buffer of 2 feet from any wall or 6 feet above the floor. This area is where grilles do their hard work of mixing supplied air with entrained air and delivering inside the occupied zone. Whether heating or cooling, the best practice is to deliver air with no perceivable draft or noise inside that zone. Airflow at or below 50 feet per minute will be unnoticed. Using the correct grille will eliminate noise. This protocol will complement a standard ac or heat pump installation.

COMPLEMENTARY CONFIGURATION: Utilizing the correct grille will eliminate noise and complement a standard heat pump installation. (Courtesy of National Comfort Institute)

These facts should convince every contractor that duct renovation should be a major consideration and income source. A business model without duct renovation avoids an income of almost double the gross profit of a business that just changes the box. Your business will always run into problems if existing ductwork is not corrected at the time the system is changed. Today’s systems do not operate well on old duct. High static pressures will cause water blowing into ducts, creating biological growth. High noise levels will be present as the newer blowers will try to maintain fan flow and comfort will remain limited.

STATIC PRESSURE: High static pressures create concerns for contractors and homeowners. (Courtesy of Tom Turner)

Our next is topic is overlooking non-dominant capacities. A very small number of areas in the U.S. have equally balanced winter and summer hours of operation, so it is easy to justify capitalizing on your climate demand. In Texas, contractors focus on cooing and in Michigan they focus on heating so it’s easy to get off track.

What makes heating and cooling loads different? Why is it important to understand the difference? Since heat has made the news lately, I can use my home state has an example.

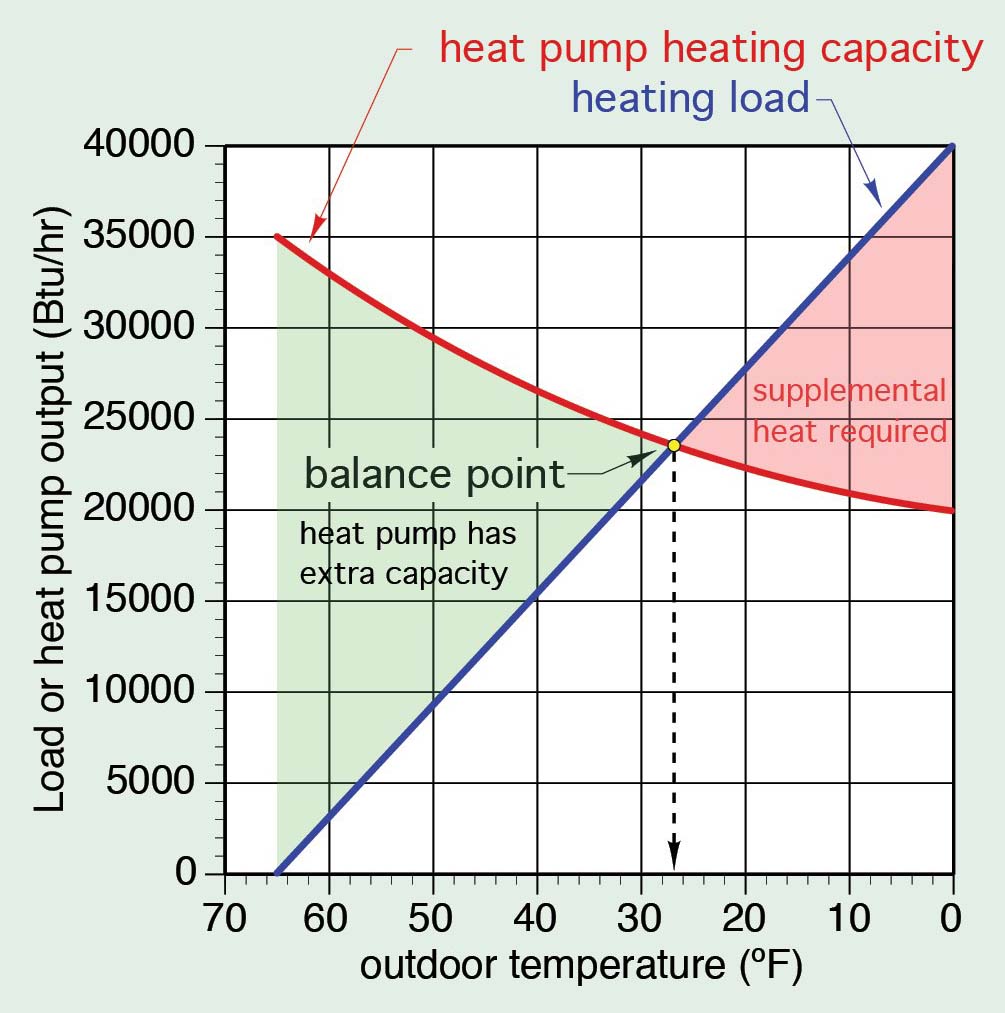

Texas has more cooling hours annually than heating hours. Almost double the cooling hours as compared to heating. This fact makes the entire state cooling dominate, and sometimes contractors focus on cooling equipment and put heating on the back burner. No pun intended. This sometimes causes oversizing of heating equipment to get enough blower capacity out of the furnace or air handler chosen, particularly when sizing above 3 nominal tons of cooling. We just don’t pay attention to heating when it’s a factor three months of the year. However, you can’t just forget sizing heat pumps for non-dominant conditions. Deltas between outdoor temperatures and indoor temperatures can’t be overlooked. During the cooling season, we generally deal with indoor temperatures somewhere around 75°, and the outdoor temperatures are 100°. This indicates we must deal with about 25° to overcome with the appropriate capacity equipment. No matter whether we have one day of 100° or 20 days, we design for the possibility of that high temperature day.

On the heating side, we deal with indoor temperatures of approximately 65°-70° and 30° outdoor temperatures. This means we deal with a delta of 40° or a 60% increase in Btu over the 25° delta in cooling. So heating loads are almost double that of cooing loads. This is where paying attention to non-dominant loads with heat pumps pays off. Again, we design for the average possibility of the temperature reaching 30°. I can hear the folks in Michigan laughing at 30° outdoor temperature. That’s almost picnic weather for them.

BALANCING POINT: The balancing point of a heat pump’s capacity and load. (Courtesy of Tom Turner)

We of course will see temperatures above 100 and below 30, but these are annual averages for design criteria. When these events exceed design criteria, run times are extended, and with that the bills will increase. In the environmental air conditioning and heating market, “bigger is never better”. You never want to oversize either side of the equation. In the cooling cycle with oversize equipment in place, we can experience shorter run times with decreased humidity control and the possibility of biological growth. With oversize heating, you can find shorter run times, not allowing all the rooms to meet a comfortable temperature. On both scenarios you can lose money on initial purchase, and operating costs.

When we apply the topics above in converting electric to heat pumps, we must at a minimum reconfigure the distribution system most of the time. When we plan a change, from fuel fired to heat pump, there are several items to remember.

- An accurate load calculation is necessary.

- Pay attention to both sides of the calculation to be sure equipment will meet capacity.

- Duct system modification will likely be required on eight of 10 jobs.

- Homes that have leakage rates over 0.4 should remain fuel fired.

- All heat pumps are not created equal.

If we think about heat pumps replacing fuel-utilized heating, caution must be used. As an example, we might purchase two 36,000-Btu heat pumps to replace a 60,000-Btu furnace in the winter conditions of 30°. We wind up wasting energy in the summer on a typical home. On the plus side, there are times when two heat pumps over a fuel fired appliance might make a difference. Where a single system heats and cools a two-story home, it may make sense to install two heat pumps in place of the single system if duct work is accessible. If ductwork is inaccessible, ductless mini splits or a combination of the above may be the answer.

Heat pumps lose heating capacity as temperatures fall, making it important to calculate loads correctly. New technology is promising, and better results at lower temperatures are available, but you must research the product you sell and understand the liabilities in place.

This time around, let’s install heat pumps that meet the customer’s needs and budget long term. Don’t forget comfort too.