Senior director of industry relations and compliance

Hillphoenix

Carbon dioxide (CO2) has been used as a safe and reliable refrigerant since the Industrial Revolution. Now, modern food retailers are adopting CO2 (R-744) as their preferred refrigerant — and for good reason. The list of advantages of using CO2 is comprehensive:

- It is a natural refrigerant;

- It is an odorless, non-corrosive, non-toxic, and nonflammable Class A1 refrigerant;

- It has no ODP and with a GWP of 1, it is the basis by which all other refrigerants are measured;

- Its high heat-reclaim capabilities improve stored-energy performance;

- It offers significant energy and operational cost savings;

- It has low service and maintenance costs since it can be vented to the atmosphere and does not have to be captured or reclaimed; and

- It doesn’t run afoul of regulatory issues, so end users won’t be subject to fines or penalties. As such, it’s future-proof.

CO2 refrigerants started competing with “synthetic refrigerants” in the 1930s, with the creation of chlorofluorocarbons (CFCs). CFCs eventually gave way to hydrofluorocarbon (HFC) refrigerants, which were considered more stable and more reliable in the higher ambient temperatures below the so-called “CO2 Equator.”

As a result, CO2 started to be seen as a secondary refrigerant. However, a series of technological innovations — coupled with the harmful effects HFCs have on the environment — helped restore CO2’s standing as a scalable sustainable refrigerant. Still, misconceptions continue to surround the use of CO2 in refrigeration systems, and some of those myths will be debunked here.

Myth: Transcritical CO2 Can’t Be Used Below the CO2 Equator

Because ambient temperatures increase the closer one gets to the Equator, the argument goes that transcritical CO2 systems shouldn’t be used below the CO2 Equator. Instead, many believe that a subcritical CO2 system should be used, which is one in which the refrigerant can be condensed.

Concerns around the CO2 Equator started to disappear about 10 years ago, due to a series of technological advances that included:

- Adiabatic gas coolers, which combine the condensing of the refrigerant with the adiabatic cooling of the air;

- High-pressure subcoolers, which use a small mechanical vapor-compression cycle coupled to the main cycle at the exit point of the condenser to provide subcooling;

- Parallel compression systems, which compress excess (flash) gas at the highest pressure level possible to improve overall energy efficiency; and

- Gas ejector systems, which recover the energy of the high-pressure side of the system to reduce the work required on the lower-pressure side of the system.

Reality: The CO2 Equator myth is no longer relevant, thanks to advances in refrigeration system technology.

Myth: CO2 Requires Significantly More Energy vs. Traditional Refrigerants

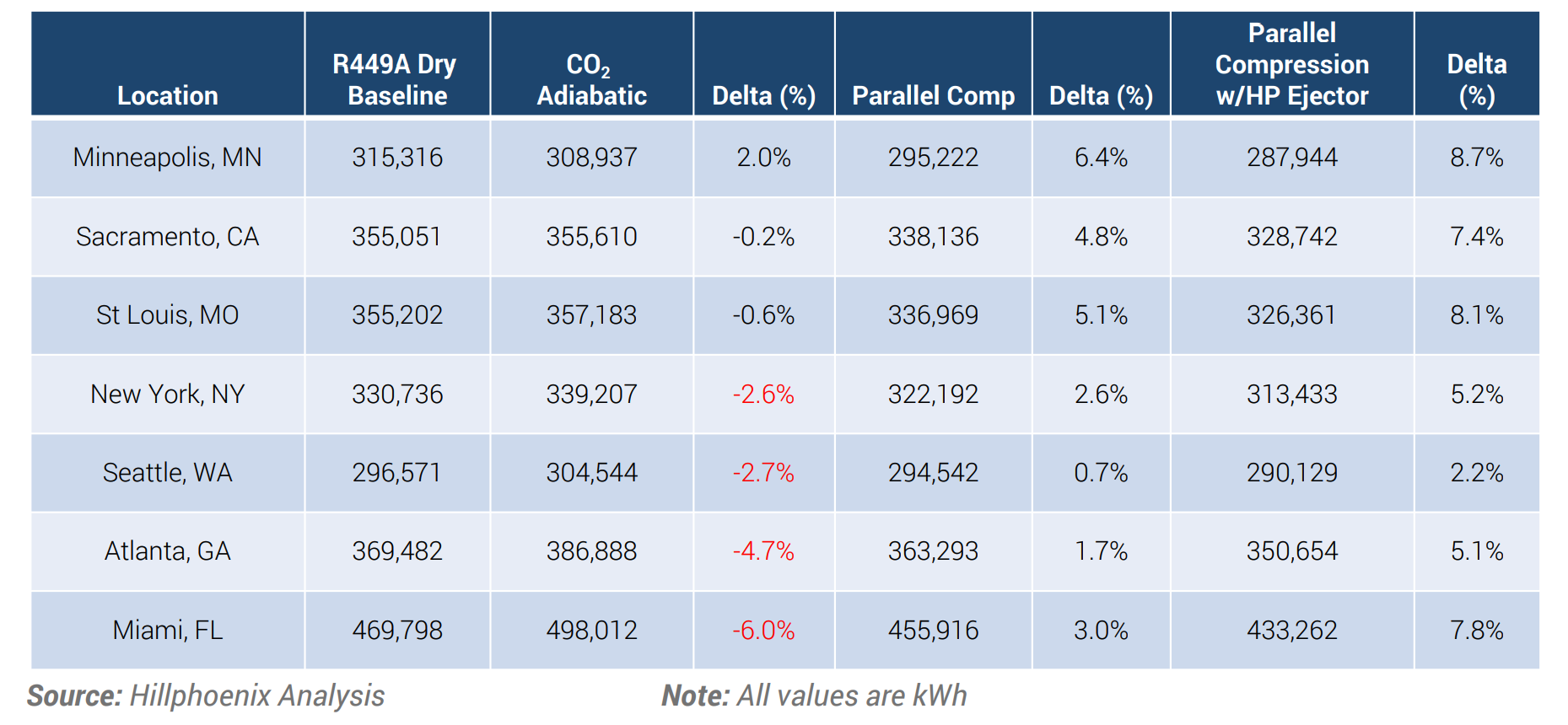

Perceptions often shape beliefs, yet a comparison between a system employing R-449A, a blend of HFOs and HFCs, and one utilizing CO2 refrigerant, sheds light on these distinctions. Side-by-side tests conducted across seven U.S. cities (Minneapolis, Sacramento, St. Louis, New York, Seattle, Atlanta, and Miami) showed that when improperly installed, a CO2 system can be 17% (in Seattle) to 22% (Miami) less efficient than an R-449A system.

However, when the CO2 system is properly designed and includes components, such as adiabatic gas coolers, parallel compressors, parallel compressors with high-pressure ejectors, and electronic expansion valves (EEVs) the CO2 system can be more efficient than the R-449A system. The problem is that many operators will mistakenly size their CO2 system according to HFC system parameters.

Reality: There are numerous energy-saving possibilities when CO2 refrigerant is used in a properly designed system, and the benefits can be compounded when additional components are employed.

Click table to enlarge

IMPROPER INSTALL: Side-by-side tests conducted across seven U.S. cities showed that when improperly installed, a CO2 system can be less efficient than an R-449A system. (Courtesy of Hillphoenix)

Myth: Energy Consumption Increases Significantly When a CO2 System Goes Supercritical

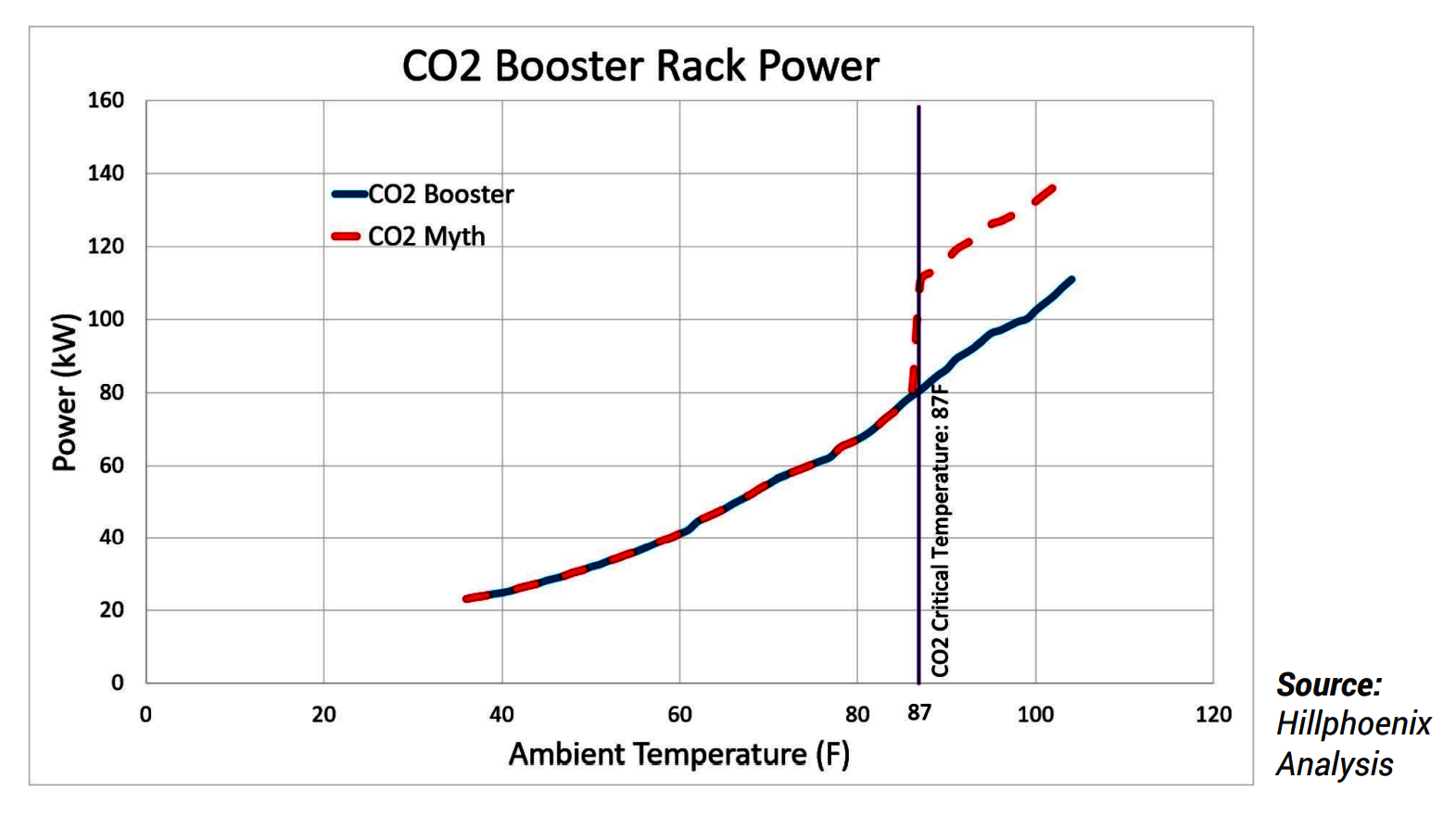

As the subcritical ambient temperature (less than 87ºF) around the refrigerant system moves toward the supercritical CO2 temperature of 87ºF, the belief is that there will be a significant and immediate spike in energy usage when the subcritical/supercritical line is crossed. This made food retailers nervous, especially in warmer climates. But when tested, the results show that so-called significant spike doesn’t happen.

Reality: While kilowatt (kW) usage does increase as the supercritical temperature threshold is passed, no drastic spike is experienced. Energy consumption increases along the same steady path as it does in subcritical temperatures — just like any other refrigerant.

Click chart to enlarge

NO SPIKE: While kilowatt usage does increase as the supercritical temperature threshold is passed, no drastic spike is experienced. (Courtesy of Hillphoenix)

Myth: CO2 Refrigeration Systems Are Too Complex

Schematic drawings of a typical CO2 system can look complex, as they feature several valves (high-pressure, electronic expansion, and flash-gas bypass), transcritical and subcritical compressors, case and rack controllers, coolers, condensers, and heat reclaim systems. That can sound like a lot to keep track of; however, advances in technology have also busted this myth.

The key innovation here is the EEV, which is much easier to work with than mechanical valves. Also, CO2 refrigerant systems can now be controlled and optimized by computers, which means every system function is read through transducers, temperature sensors, and analog and digital inputs. Operation is reported/recorded via electronic software and hardware, so an effective computer-controlled system is all you need to ensure proper operation. That eliminates the need for a technician to constantly monitor and manually adjust the system’s valves and other components.

Reality: While the design and components of CO2 refrigerant systems are similar to those used for many years, electronically controlled components make them more reliable and give them longer service life. This results in a decidedly less complex and more robust system.

Part 2 of this article dispels even more myths about CO2 refrigeration systems.