At a recent meeting of the International Ground Source Heat Pump Association (IGSPHA), Enertech business development manager Rob Derksen shared tips for how HVAC contractors can become better at promoting geothermal heat pump technology. His first piece of advice was to educate the community. As geothermal heat pumps gain more presence as the environmentally-conscious alternative for heating and cooling in commercial settings — such as schools, apartment buildings, hotels, and retirement homes — technicians and customers alike will need to be informed on the basics of how a water-source heat pump (WSHP) works.

All Geothermal Systems are Water-Source Heat Pumps, But Not All Water-Source Heat Pumps are Geothermal

At the heart of every geothermal system is a heat pump, and every geothermal heat pump is “water-sourced,” which means they use water to remove heat in cooling mode and to add heat in heating mode. In geothermal, the source of the water’s heat and the “sink,” where excess heat is rejected, is the Earth. The water loop goes through pipes buried underground or submerged in a pond. If the system is not geothermal, then it uses a cooler and a hot water generator.

How a Heat Pump Works

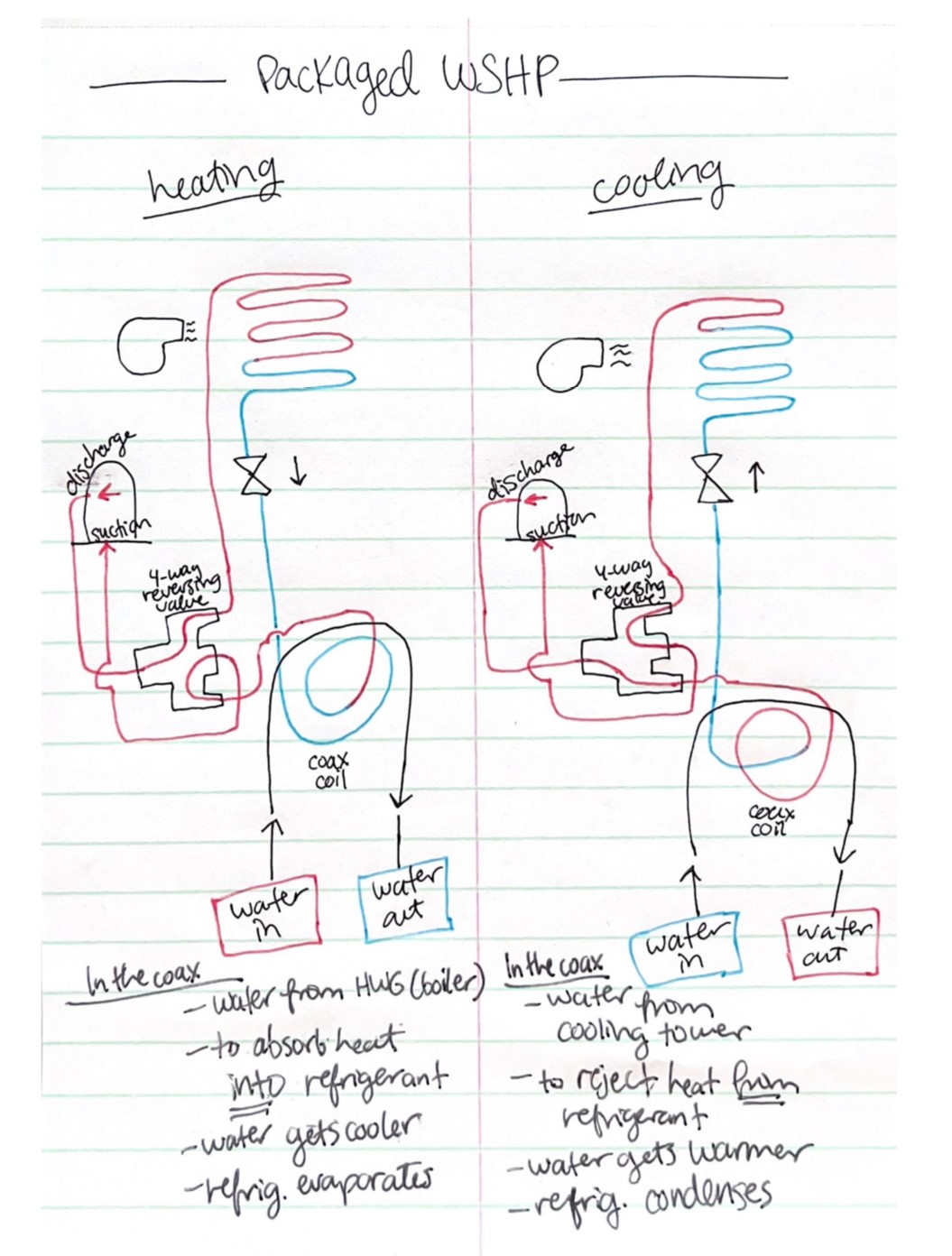

Heat pumps use the refrigeration cycle to provide cooling just like a regular air conditioner; however, in heating, the heat pump reverses this cycle to provide warm air for the space. This reversal occurs when the two coils (the evaporator and condenser) switch roles. Instead of sending hot refrigerant gas to the condenser coil, the compressed refrigerant is sent to the evaporator where it rejects heat into the space.

To accomplish the coil-switching, all heat pumps have a four-way reversing valve (see Fig. 1). The valve always has one port by itself which has compressor discharge gas going into the valve, and on the other side, there are three ports: one that directs refrigerant back to the compressor, and the other two going to each coil. The reversing valve is operated by a solenoid valve, which, when energized, moves the valve to change which coil the refrigerant goes to. Most heat pumps energize the valve on a call for cooling. This way, if the valve fails, it fails in heating mode. Manufacturers typically program a five-minute delay between heating and cooling mode to prevent wear and tear on the reversing valve.

FIGURE 1: The reversing valve is operated by a solenoid valve, which, when energized, moves the valve to change which coil the refrigerant goes to. (Courtesy of Lianna Schwalenberg)

How Water Absorbs and Rejects Heat

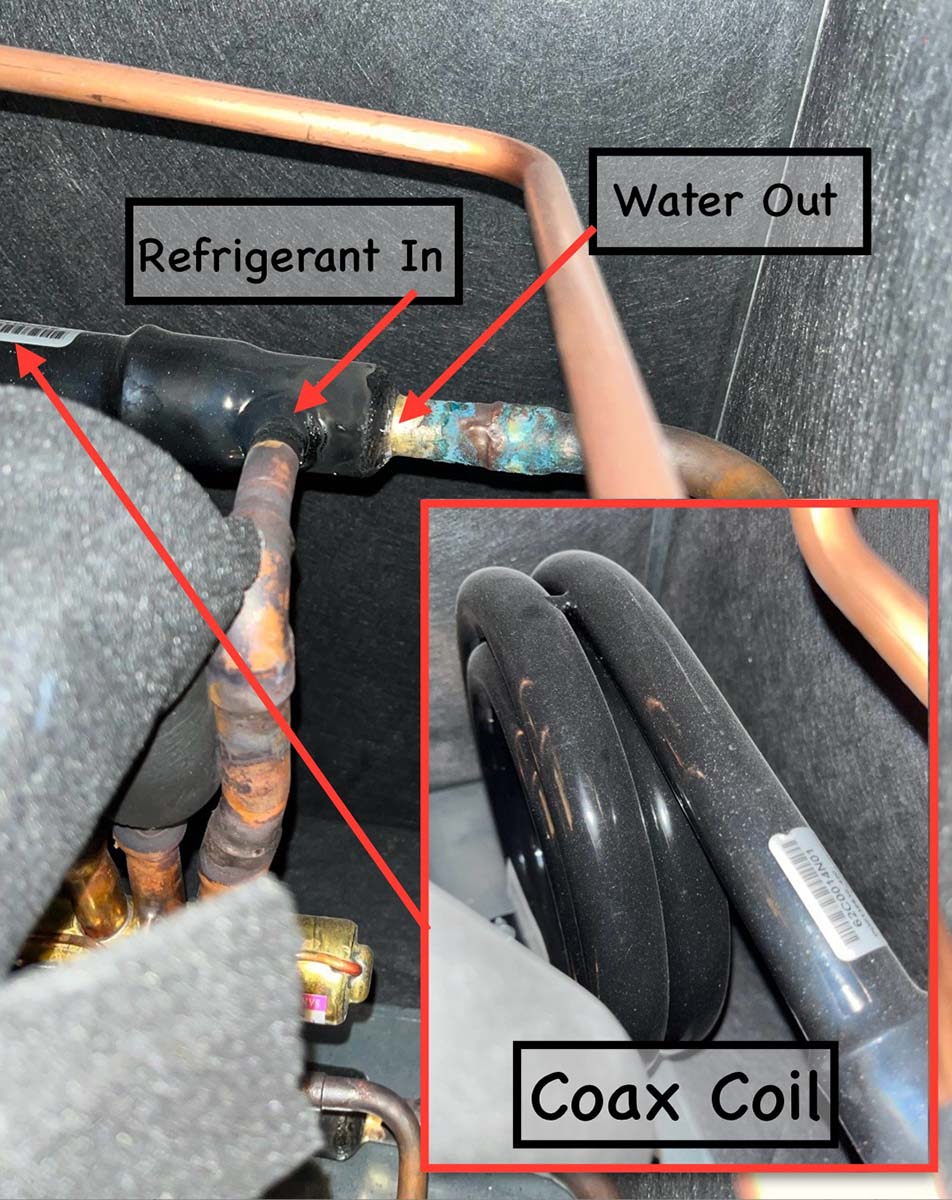

In WSHPs, the condenser is often referred to as a “coax coil.” It consists of two copper pipes spun together in a coiled loop shape (see Fig. 2). Without mixing, this is how the water comes into contact with the refrigerant to absorb and reject heat. The water and refrigerant flow counter to each other.

FIGURE 2: The coax coil consists of two copper pipes spun together in a coiled loop shape. (Courtesy of Lianna Schwalenberg)

Similar to how a regular heat pump works, water-source heat pumps also use a reversing valve to change where compressed hot gas refrigerant goes. In air conditioning mode, the WSHP sends hot gas refrigerant to the coax coil where heat is rejected. In heating mode, the reversing valve sends compressed hot gas refrigerant into the evaporator coil — which looks like a standard air coil — where heat from the refrigerant is rejected into the indoor space and where the refrigerant condenses. After which, the condensed liquid refrigerant uses the heat from the water coil to evaporate. And thus, the refrigeration cycle continues (see Fig. 3).

All WSHPs are “packaged” meaning the unit contains the entire refrigeration cycle. These units are small enough to be installed in a closet or cabinet in the wall, making them a great option for apartment-style homes. During installation, all that needs to be connected besides the electrical and a condensate drainage system are two pipes: one for water-in and one for water-out. Of course, the system also requires ductwork to distribute the air throughout the space.

Click diagram to enlarge

FIGURE 3: Heat pumps use the refrigeration cycle to provide cooling just like a regular air conditioner; however, in heating, the heat pump reverses this cycle to provide warm indoor air. (Courtesy of Lianna Schwalenberg)

The Water Loop

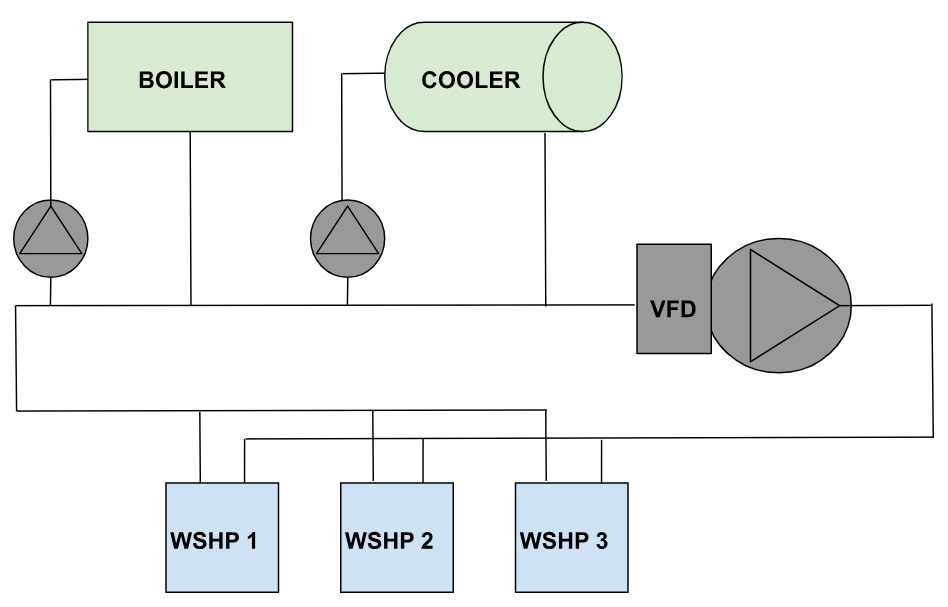

The water is in a main loop connected to a hot water generator — typically a boiler — and a cooler. The cooler can be a closed-loop evaporative cooling tower, or a chiller system, which uses the refrigeration cycle to cool the loop water. The purpose of the cooler and boiler is to maintain the water loop at a designed constant temperature — between 65-95° Fahrenheit (commonly 70°) — at all times, regardless of the units’ demands or the outdoor temperature (see Fig. 4). This water loop acts as both a “sink” and “source” of heat energy.

It may surprise some to think that 70° can accomplish both heating and cooling. However, because these systems use the refrigeration cycle, 70° actually has a significant amount of “space” to hold and give heat. Think of it like operating an air conditioner when it’s 70° outside or likewise operating a heat pump in heating when it’s 70° outside. Just like with air, this too can be accomplished with water.

If the building is many stories tall, there will typically be custom-built pump skids on every floor or every other floor to maintain flow without the need for extremely large pumps or boilers and chillers on every floor. If the loop water ever has to go outside, sometimes the water will be mixed with glycol to lower its freezing point.

FIGURE 4: The primary purpose of the chiller and boiler is to maintain the water loop at a constant temperature at all times, regardless of all the units’ demands or the temperature outside. (Courtesy of Lianna Schwalenberg)

Maintenance Considerations

Like any air-handling system, these units have air filters that must be changed regularly. These units also have wye strainers on the water-inlet side to catch debris. To remove the wye strainer screen, turn off the valve, bleed the pressure and use two wrenches to remove the cap. These strainer screens do not necessarily need to be cleaned as often the filters are changed. Checking a temperature or PSI differential will indicate if they are clogged. The temperature difference between the incoming and outgoing water is typically 10°. A 20° difference or more is a sign that the strainer screen could be restricted.

As with maintaining a regular air conditioner, it is also good practice to check the evaporator drain pan and make sure it is clear and drains well.

HVAC service technician

The K Company

Troubleshooting

The most common problems are the following: poor water flow, poor airflow, refrigerant leaks, water leaks, and component failures. It is recommended to have a spare unit on site in case a part fails in emergency situations. Water flow problems are akin to a dirty condenser coil whereby the transfer of heat is restricted.

Because these systems are very small–typically only a couple pounds of refrigerant–the recommended way to check charge is to first check the temperature rise and drop. As with any heat pump, the temperature rise is not as impressive as a gas furnace, but in both heating and cooling, you will typically see 20-30° splits between return and supply air. If the temperature split is very low, and after you have ruled out air-flow and water-flow problems, then you can use a low-loss fitting or a thumbscrew core depressor to check the charge. These tools prevent refrigerant from escaping which is especially important to consider when you are in a space as small as an apartment living room or hallway closet. These systems always arrive factory-charged, and because there are no line sets, you will typically not have or need a charging chart. A WSHP that is low on refrigerant behaves the same way as a regular air conditioner low on charge, and when it is time to add the charge, simply weigh it in.