As the HVAC industry transitions from high-GWP HFCs like R-410A to mildly flammable alternative refrigerants (A2Ls), it's understandable that those working with these new products have many questions. In this article, we address many of the top questions HVAC professionals have about these low-GWP refrigerants.

What are refrigerant classifications?

Refrigerants are categorized based on toxicity and flammability and assigned respective refrigerant concentration limits by ASHRAE® Standard 34. This is an alphanumeric system, where letters A and B denote lower toxicity and higher toxicity respectively, and the numeral 1 denotes no flame propagation, 2L denotes lower flammability, 2 denotes flammable and 3 denotes higher flammability.

What is low global warming potential (GWP) classification?

GWP numbers for a refrigerant are calculated and published by the United Nations Intergovernmental Panel on Climate Change (IPCC). The GWP number is based on the refrigerant’s properties, such as lifetime, radiative forcing effect, and current atmospheric conditions such as abundance of CO2 gas. Consequently, GWP numbers have changed over time. However, most notable regulations such as the Kigali Amendment of the Montreal Protocol, CARB Prohibitions on Use of Certain Hydrofluorocarbons in Stationary Refrigeration, Stationary Air-conditioning and Other End-Uses, and the AIM act, are based on the IPCC’s 4th Assessment Report (IPCC AR4) values. Regulatory bodies have used the IPCC AR4 values to develop policies and identified refrigerants with a GWP of less than 750 as lower GWP candidates.

What are single component and blend refrigerants?

Single component refrigerants are comprised of only one type of molecule, so they have a constant evaporation and condensation temperature at a given pressure. On the contrary, blend refrigerants are a combination of two or more single component refrigerants that are carefully formulated and composed to strengthen or compensate for certain properties.

What are the benefits of a single component refrigerant compared to blends?

Single component refrigerants are simpler to handle than most blends. Single component refrigerants do not have a temperature glide; refrigerant charging can be performed in liquid or gas phase even with an upright cylinder; there is no negative performance impact due to composition change; it can be easily reclaimed, recycled, and after reused and its production cannot be restricted by patents, as is the case for many newer low GWP blends.

What is temperature glide?

Temperature glide is variability in boiling temperature of a refrigerant fluid due to the fraction of liquid and vapor at a given pressure condition. This is an undesirable characteristic that can compromise optimal performance of an HVAC system.

What is critical temperature (CT)?

Critical temperature is the temperature above which a pressure change cannot liquefy the refrigerant, no matter how much pressure is applied. Higher critical temperatures allow for greater heat transfer at a constant temperature and is thus desirable for better efficiency.

What is lower flammability limit (LFL)?

LFL is the minimum concentration of a refrigerant that is capable of propagating a flame under specific test conditions. A higher LFL is desired because it means a higher concentration is required to create flammable conditions. LFL for lighter fluid – butane is 1.7% (%vol), compared to R-32’s 14.4% (%vol).

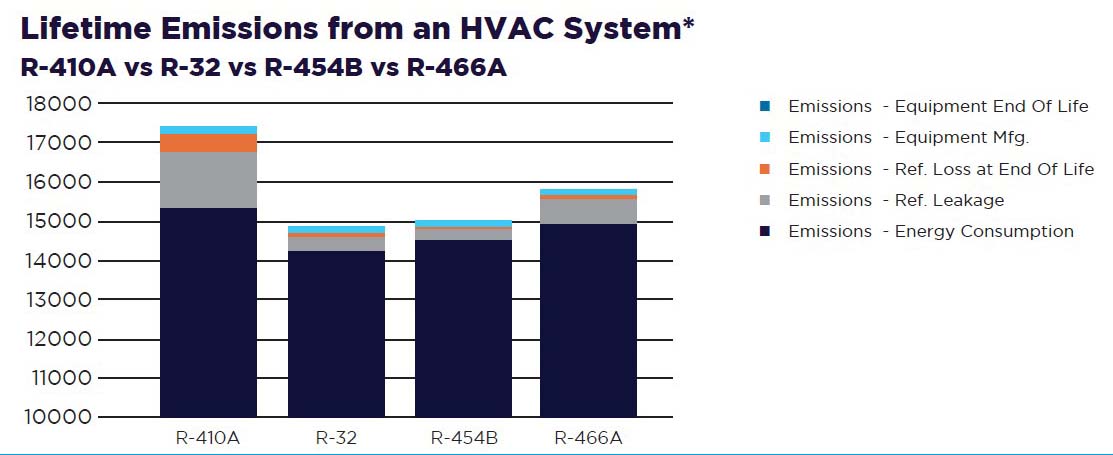

What are lifetime emissions? why is it important to consider lifetime emissions over direct emissions?

Lifetime Emissions (kg CO2.eq) from a system are a sum total of its Direct and Indirect Emissions. – Simply stated, Direct Emissions relate to the refrigerant type and its GWP whereas Indirect Emissions relate to equipment manufacturing and use in its lifetime. – Direct Emissions will be lower for a lower GWP refrigerant because it is calculated as kgrefrigerant leaked * GWP. However, an HVAC system is designed to reduce leakage and not release refrigerant to the atmosphere. But, Direct Emissions typically contribute up to 11% of a systems total Lifetime Emissions. – Indirect Emissions make up more than 89% of a systems Lifetime Emissions. – Thus, efficiency of the system is a very important criteria in choosing a refrigerant for effective reduction of GHG emissions. R-32 refrigerant’s increased efficiency helps OEM engineers design systems with low electricity consumption over the system’s life, compensating for Direct Emissions, and resulting in lower Lifetime Emissions than other lower GWP blends.

Click graph to enlarge (Courtesy of Daikin)

* Comparison is made using the Life Cycle Climate Performance (LCCP) metric, measured in kg-CO2.eq. LCCP analysis was performed using a high efficiency HP (24+SEER), using performance gains claimed by respective refrigerant manufacturer, for a residential sized (9000 Btu/h cooling capacity), installed in Houston, TX climatezone, with an assumed annual leakage rate of 4% and end of life refrigerant leakage of 15% with a 15 year lifetime. The heating COP and SEER were adjusted based on refrigerant characteristics and performance. The physical system size, trim charge requirements and capacity were kept consistent to ensure a like-to-like comparison.