Service and Maintenance

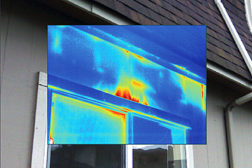

Expand Your HVAC Business with Home Energy Audits

Homeowners Are Looking for Ways to Save Energy and Money; Here’s How HVAC Professionals Can Help

October 6, 2014

Ammonia Chiller Provides Tailor-Made Refrigeration Solution for Ice Rink

Chiller Features a Very Low Ammonia Charge

August 18, 2014

10 Easy Maintenance Tips to Save Energy on Cooling Towers

A Well Maintained Unit Will Continue to Function at the Original Optimum Efficiency

August 4, 2014

Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing