Technical

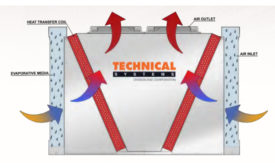

Anti-Microbial Option in Chiller/Cooling Tower Applications

Innovative design hinders the growth of hazardous cooling tower-borne pathogens

July 24, 2017

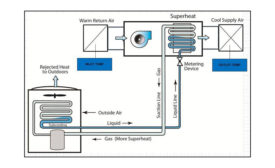

Adiabatic Technology Helps Cooling Keep Pace with Data Center Growth

More efficient cooling technology helps provide more computer power in same space

July 10, 2017

The Value of Remote Residential HVAC Monitoring and Diagnostics

It's a win-win for contractors and homeowners

Read More

Welding Shop Design for Educational Facilities

Should government regulations for hexavalent chromium be relaxed?

Read More

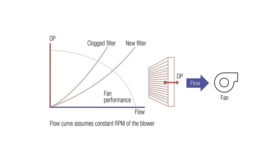

Proper Filter Monitoring

More often than not, filters are being changed too late

May 22, 2017

Calnetix Technologies Supplies Key Components for New US Navy Chiller System

High-efficiency super capacity chiller system successfully completes certification tests

May 8, 2017

Increase Marijuana Yield with Custom Refrigeration Units

New system handles daytime temperature and nighttime humidity with a single system

April 17, 2017

New Research from NIST Identifies Research Needs for Alternative Refrigerants

Researchers must look beyond nonflammable chemicals

April 3, 2017

Old Induction Units: Tear Out or Replace?

Facility managers face critical decisions when replacing aging induction units

March 20, 2017

Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing