Articles by John Tomczyk

Composition of the liquid and vapor phases differ due to phase changes

Read More

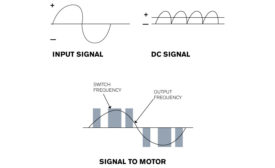

The Professor: Controlling Motor Speed with VFDs

Benefits include improved comfort and energy efficiency

Read More

The Professor: Foiling Frosted Evaporator Coils

Reduced airflow over the coil can cause a multitude of woes

Read More

The Professor: Preventing Refrigerant Migration

A number of bad things can happen when refrigerant migrates

Read More

The Professor: Symptoms of Air in a Refrigeration System

Air May Cause a Reduction in Condensing Surface Area and High Head Pressures

Read More

The Professor: Cooling Capacity Conundrum

Sly Sleuthing Solves a Supermarket Service Scenario

Read More

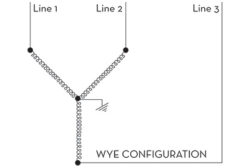

The Professor: Diagnosing Compressor Motor Overheating

Performing a Three-phase Compressor Voltage Check, Step by Step

Read More

The Professor: Wireless Superheat and Subcooling Checks

New Technology Makes Technicians’ Lives Easier

Read More

Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing