John Siegenthaler, PE

John Siegenthaler, P.E.

Principal of Appropriate Designs

john@hydronicpros.com

Principal of Appropriate Designs

john@hydronicpros.com

The third edition of his book, Modern Hydronic Heating,

is now available. For details, visit www.hydronicpros.com.

ARTICLES

A Unique Air-to-water Heat Pump System Rivals Geothermal System Efficiency

Read More

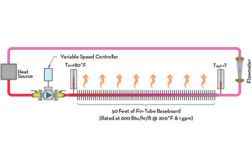

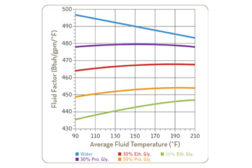

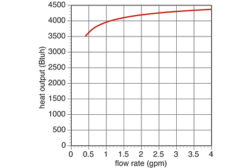

German Water: How Flow Rate Affects Heat Output

It’s OK to Design a System Outside of a 20°F Delta T

Read More

Hydronic Radiant Ceiling Cooling for Smaller Buildings

Though More Expensive, Radiant Trumps Forced Air in Comfort

Read More

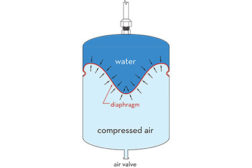

Expansion Tank Pressurization

Improper Air-side Pressurization ‘Wastes’ some of the Internal Volume

Read More

Contrasting Rules of Thumb, Calculations

Using Accurate Numbers is the Professional Thing to Do

Read More

Heat Transfer: Nature Versus Math

Formulas and Assumptions Don’t Always Predict what Happens

Read More

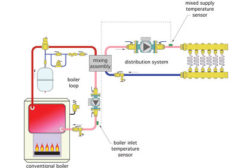

Missing: Self Buffering & Low Head Loss

Considering Circulators and Head Loss in Modern Boiler Systems

Read More

Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing