Home » Keywords: » chiller maintenance

Items Tagged with 'chiller maintenance'

ARTICLES

This white paper describes how FT Energy Controls’ FlowBridge and ClimateControl technologies can be used to reduce costs

Read More

Preparing For Emerging Cybersecurity Attacks Against Chillers

What Protocols Need to be in Place For When Malicious Actors Come Knocking

Read More

Don’t Let the Massive Emergence of Cicadas Bug Your Cooling Tower Performance

Goodway Technologies offers best practices for keeping cooling towers clean

May 8, 2024

Cooling Chillers: A Primer

Experts discuss different chiller systems, their technologies, and applications

Read More

Chillers Provide Ideal Conditions For Cannabis

Chilled water systems offer optimal environment and energy savings in large grow facilities

October 27, 2021

Chiller Manufacturers Respond to Needs of In-Demand Markets

Data centers, schools need chiller upgrades due to pandemic shifts

Read More

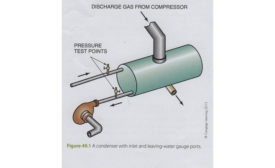

How to Conduct Chiller Maintenance

The first step is to make sure the customer understands why it’s important

Read More

Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing