Bob and Tim have responded to a service request where the customer is explaining that their heat pump is running all the time. The indicator light on their thermostat is lit most of the time, indicating the strip heat is on as well. The weather is cold today but has been warm some days and cold some days. It’s a very unusual heating season.

When they go to the whole house thermostat, they see that it is set at 71°F, and the house temperature is 69°. The indicator light on the thermostat shows that the strip heat is operating. They get their tools and meter and check the strip heating elements. They find that there are three stages of strip heat, but none of them are heating — they are not drawing current. They push the reset button on one of the heaters, and it starts drawing current. So they push the reset on the other two heaters, and all three are drawing current.

“Go to the room thermostat, and turn the heat off. We’re going to let all three of these heaters cool down slowly with the fan, so that they won’t trip off on overheat again. I suspect very low air flow through the system, which would cause the heaters to overheat. We need to start looking for low air flow problems,” Bob said.

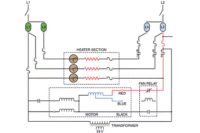

“Let’s go over the possibilities of low airflow,” said Tim (Figure 1).

“This is a relatively old system, so I think we can rule out design problems because it hasn’t had this kind of problem in the past. The first things to check for are:

- Dirty filters

- Dirty coils or fans

- Obstructions in the return air

- Discharge register dampers

These four things are quite common in all systems and should be checked regularly on a maintenance contract. However, this system has never been under a maintenance contract at our company. Let’s go look at these four items and see what we see,” Bob said.

- They looked at the filters, and they were slightly dirty so they changed them

- They checked the coil and fan and found the coil was very dirty, and the fan wheel had a lot of debris, which would reduce the airflow considerably

- Then, they looked at the return air registers and found that they were free of obstacles and had full airflow

- They looked at the discharge registers and found all of them were opened wide for full flow

“I think we have found the problem with the dirty coil and dirty fan and verified the rest of the system is okay,” Tim said.

Bob agreed and said, “Let’s get set up and clean the coil and remove the fan wheel to the outside where we can wash it down really well and get all the dirt out of it.”

After they performed all of these procedures, they put the system back together and started it. They had full airflow, so they let the system run for a while, and everything seemed to be going well. All three strip heat systems cut off, and just the heat pump itself was running. They checked the discharge air temperature, and it was running at 98°, which would be well within a normal range. They also verified the airflow. If the temperature had been running higher, around 110°, they would have suspected they still had low airflow.

They talked to the homeowner about what they had done and about a maintenance contract on the system, explaining that these problems would have been detected during a contract service call. That would have taken the place of the regular service call that they were now on. Bob also explained to the homeowner that operating a heat pump with low airflow like this one was operating was very hard on the compressor system, not to mention it would cause a higher power bill for the amount of heat that they were able to get from the unit.

The homeowner then told Bob that they had noticed their power bill had been up this year during heating season and had wondered why. The customer then said that he would like a service contract agreement and Bob gave him one to fill out and mail to the company.

“We have only looked at the indoor portion of this unit. We need to examine the outdoor unit and make sure everything is okay with it,” Bob informed the customer.

Tim asked Bob, “Is this common with a system that has been installed for quite a while? Why didn’t the air filter catch that dirt?”

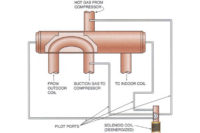

“Yes it is fairly common because air filters have different filtering abilities. This is an older system and has the older, low-efficiency air filters (Figure 2). This filter is one of the very cheap ones probably purchased at a big box store. They are probably only about 5-10 percent efficient and only filter out large particles such as feathers and gum wrappers. Small dirt goes right through them, with only a small amount of that dirt being collected on filter element. The filter is actually more efficient as it begins to become restricted because the air passages become smaller as they become dirty,” Bob said.

“Why don’t we just put the new high-efficient air filters in the system?” Tim asked.

“Higher filtration is accomplished with smaller air passages through the filters. If you put the same sized high-efficiency air filter in this system, it will reduce the airflow considerably. Enough to cause problems. To go to a high-efficiency air filter, we would need to build a larger filter box, and install a larger, higher efficiency filter. That is not really cost-effective for an older system. When this system plays out, the new system will have high density air filters in it. The system is fairly old, so it won’t be many years until a new system will be needed.

While we are here, we need to perform a complete service call on this system and check it all out just as we would on a service contract,” said Bob.

They turned their attention to the outdoor coil as they had oiled the indoor fan motor while they had it out cleaning the blades.

The outdoor coil was dirty, so they pressure washed it by removing the fan housing and spraying detergent over the entire coil surface area, on the inside and the outside. They let the detergent soak in for a few minutes and then, using the pressure washer, they blew from the inside out, being careful to blow straight into the fins to keep from laying them over opposite the direction of the airflow. Dirt and accumulation just rolled off the coil.

They oiled the outdoor fan motor and checked the contactor contacts, which were fairly worn out. As a result, they installed a new contactor.

Before they left, they explained to the homeowner that what they had done would greatly improve the efficiency and the lifespan of their unit.

As they were leaving, Tim said, “We did a good job on that service call, I am very satisfied that the customer got his money’s worth.”

“It is always good to know the customer got their money’s worth and that they know it. All customers want good value for what they pay for,” Bob said, agreeing with Tim.

Publication date: 2/20/2017

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!