It’s impossible to balance line-to-line voltages perfectly in three-phase circuits, so they typically differ by a few volts or more. However, if voltage unbalance exceeds 1%, it can markedly decrease the performance and energy efficiency of three-phase motors while increasing the likelihood of premature failure. Avoiding these issues requires a proactive approach that includes installing adequate protective devices and periodically checking for voltage unbalance at the motor terminals.

What It Is

Voltage unbalance is not the same thing as voltage variation (deviation from the rated voltage). Rather, it describes the condition when the line voltages in a three-phase circuit are not all equal. How this will affect motors and other devices in the circuit depends on the percent unbalance that is present, as defined in NEMA Stds. MG 1-2014, Part 14.36:

% voltage unbalance =

100 x (maximum voltage deviation from average voltage)

(average voltage)

With line-to-line voltages of 472, 462, and 479, for example, the average voltage is 471, and the maximum deviation from average is 9. Therefore the percent unbalance is 1.91%:

100 x (9/471) = 1.91 %

Acknowledging possible differences in performance, NEMA Stds. MG 1, Part 12.45, calls for three-phase motors to “operate successfully” at rated load if voltage unbalance at the motor terminals is 1% or less. For reliable motor operation, be sure to keep this limiting value in mind. (Note that the 1.91% unbalance in the above example exceeds the NEMA standard.)

Common Causes

Unbalanced voltages can exist anywhere in a three-phase power distribution system. Usually, the source of the problem is unequal line loads due to system voltage unbalance, different system impedances (voltage divided by current), the nature of the loads, and the operating load on equipment, particularly motors. “Single-phasing” (the complete loss of a phase) is the ultimate voltage unbalance condition for a three-phase circuit.

Frequent causes of unbalanced voltages include:

- Unbalanced incoming utility supply

- Unequal transformer tap settings

- A large single-phase distribution transformer on the system

- An open phase on the primary of a three-phase distribution transformer

- Faults or grounds in the power transformer

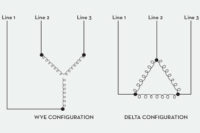

- Open delta-connected transformer banks

- A blown fuse on a bank of three-phase power factor improvement capacitors

- Unequal impedance in conductors of power supply wiring

-

Unbalanced distribution of single-phase loads, such as lighting

Effects Of Voltage Unbalance

Additional heating. Voltage unbalance produces even larger phase current unbalances that can damage electric motors, generators, transformers, and power supply wiring. For example, voltage unbalance of 1% at the terminals of a fully loaded motor can result in phase current unbalance of 6-10%. This raises the operating temperature of the motor, which reduces its energy efficiency and shortens its life.

The additional heating (called “winding losses”) is calculated by the formula I2R, with I being current and R resistance. If the current unbalance is 10% (1.10), the high-current phase will have at least 21% (1.102 = 1.21) more loss (loss = heat) than any other phase.

Table 1 clearly shows how voltage unbalance affects the current and temperature rise of a typical three-phase electric motor rated 5 hp, 230/460V, 60 Hz, 1,725 rpm, and 1.0 service factor.

Each 10°C (18°F) above the rated temperature rise will shorten the life of winding insulation by about half, so even a small increase in the percent voltage unbalance could seriously damage a motor. The 5.4% voltage unbalance in Figure 1 adds 60°C (108°F) to the temperature rise, which means the life expectancy of the winding (and motor) would drop to about 1/64 of normal — a substantial and unacceptable reduction.

Harmonic currents. Unbalanced voltages also can introduce harmful harmonic currents. Although beyond the scope of this article, these currents cause additional heating in motors and supply wiring (sometimes including the neutral). The percentage of harmonic current may increase significantly due to both third- and even-order harmonics in the circuit.

Other effects. Other effects of unbalanced voltages on motors are that the locked-rotor current of the stator winding (already relatively high) will be unbalanced in proportion to the voltage unbalance, full-load speed will drop slightly, and torque capability will decrease. If the condition is severe enough, the motor may not produce enough torque to reach rated speed. Noise and vibration levels also can increase due to voltage unbalance.

A word of caution. Not all voltage unbalances are created equal. The effect is more dramatic if the voltages of all three phases differ than if only one phase deviates from the other two. This is true even if the percent variation calculates to the same unbalance.

Figure 1 illustrates the typical percentage increases in motor losses and heating for various levels of voltage unbalance.

Motors often continue to operate on unbalanced voltages, but do so less efficiently because of the increased current (I) and greater resistance (R) due to heating. These factors “stack up,” producing an exponential increase in motor heating that sometimes leads to “thermal runaway” (uncontrollable heat rise), rapid deterioration of the insulation system, and premature winding failure.

Single-phasing. Single-phase operation of a three-phase motor deserves special attention because it decreases output capability and causes excessive currents and overheating. If single-phasing occurs at or near full load, the motor will not develop rated torque and may even stall —i.e., come to a stop. The stall condition generates tremendous amounts of locked-rotor current, which triggers an extremely rapid temperature rise.

Electrical maintenance people often rely on a motor protection device to prevent loss of phase, only to find that it did not work and the motor has failed. An interesting example is what would happen if a pump motor lost a phase. Recall the formulas for AC power:

Single-phase: P = V x A x pf

Three-phase: P = V x A x pf x 1.73

(where P = watts, V = volts, A = amperes, and pf = power factor)

If the three-phase motor supply becomes single-phased, the output power capability would drop to 1/1.73, or about 58% of rated, and rotor speed would decrease significantly due to the reduced torque capability. Pump power varies by cube of the speed, so the power requirement would also drop. Since the motor current may not be significantly above rated, the overload protection devices would not trip. Still, reduced cooling at the slower speed could cause the motor to overheat and fail prematurely.

Without adequate motor protection, the stator winding may fail and the squirrel cage rotor also may be damaged or destroyed. A good reason not to rely on standard, three-overload starters to prevent single-phasing is that motor windings can overheat even when line currents do not exceed the setting of any one overload device. Effective protection against single-phasing requires special sensing devices such as negative-sequence voltage relays (discussed later).

Testing For Unbalanced Voltages And Single-Phasing

To test for unbalanced voltages, measure the line-to-line voltages at the motor terminals (following all applicable safety precautions) and then determine the percent voltage unbalance as explained earlier. As a check, measure the current in each supply line because current unbalance is often six to 10 times greater than the percent voltage unbalance. The percent voltage unbalance should not exceed 1% for successful motor operation.

Suspect single-phasing if a motor fails to start; confirm it by measuring the current in each phase of the circuit. One phase will carry zero current when a single-phasing condition exists.

Ways To Correct Unbalanced Voltages

Redistribute unequal loads. Redistributing heavy single-phase loads (e.g., lighting equipment and occasionally welders) equally among phases can reduce voltage unbalance caused by excessively unequal load distribution. In addition, check for a blown fuse on a bank of three-phase power factor improvement capacitors.

Derate the motor. Another corrective action, though generally undesirable, is to derate the motor. If voltage unbalance exceeds 1%, a motor must be derated to operate successfully. Figure 2 indicates that at the 5% voltage unbalance limit set by NEMA a motor must be derated substantially to about 75% of its nameplate horsepower rating.

Install automatic voltage regulators (AVRs). AVRs can be used to correct voltage unbalance, as well as undervoltage and overvoltage. These devices automatically compensate for all voltage fluctuations in real time if the input voltage is within their range of magnitude and speed of adjustment. Usually it is more practical to protect the various circuits with several smaller units than with one high-power AVR at the plant service entrance.

Use protective relays. Special protective relays can detect voltage unbalance and shield equipment from its degrading effects. Typically, these unbalance relays are small, relatively inexpensive microprocessors with numerous features — e.g., automatic or manual reset, programmable trip time, and unbalance limit settings. If voltage unbalance exceeds a predetermined limit, most of these devices can activate an alarm, trip a control, or both. They also can be retrofitted into a motor control circuit or any portion of a power distribution system.

Negative-sequence voltage relays can detect single-phasing, phase-voltage unbalance, and reversal of supply phase rotation. These relays only sense anomalies upstream of their location in a circuit so they cannot detect a problem in a motor or other load downstream.

Other relays that provide only limited protection in specific circumstances include phase-sequence undervoltage relays and phase-voltage relays. Phase-sequence undervoltage relays usually do not provide satisfactory phase-loss protection because, as mentioned previously, single-phased motors may generate enough voltage to make it appear that a relatively balanced condition exists. Phase-voltage relays provide only limited single-phasing protection by preventing the motor from starting if one phase of the system is open.

A Closing Point

As mentioned earlier, voltage unbalance and voltage variation are very different things. Voltage variation is the deviation of voltage from the rated voltage, and NEMA Stds. MG 1-2014, Part 12.68, allows a variation from rated voltage of ± 10%. That rating assumes balanced voltages and acknowledges that motor performance will not necessarily be the same as at rated voltage. The tolerance for voltage unbalance is only 1%, an order of magnitude less than the 10% tolerance for voltage variation. ES