To achieve peak efficiency and prevent corrosion, steam and hot water boilers in hydronic heating systems require regular maintenance. Neglecting this can lead to increased service calls and a significantly reduced lifespan for the heating system. The cost of replacing a heating system can be up to thousands of dollars for home and building owners. To avoid such expenses, it's advisable to invest in annual maintenance services to extend the life of the heating systems and defer major costs.

When it comes to servicing or flushing hydronic heating systems, there are a few best practices to follow. These systems operate on the principle that water expands when heated and contracts when cooled, a phenomenon known as thermal expansion. This is the tendency of matter to change shape, area, volume, and density in response to temperature changes. To manage thermal expansion, systems must include storage capacity.

There are two main types of systems that accommodate thermal expansion: closed-loop (sealed) systems and open-loop (vented) systems. Each type requires a different approach to servicing and maintenance. Before exploring the specifics of flushing a heating system, it's important to understand the distinctions between a closed- and an open loop system.

Closed loop

In short, a closed-loop system is sealed off from the atmosphere, incorporating expansion tanks to manage water's expansion and contraction. Unlike open-loop systems, it features a dedicated return line, ensuring water is cycled back to the heating source (typically a boiler). This design prevents the mixing of warm and cold spots in the water supply.

Closed-loop systems, often smaller than their open-loop counterparts, not only require less space but also enhance cleanliness, improve water quality, and minimize oxygen entry, thereby reducing the risk of corrosion. With a closed loop, the potential for water ingress is lessened, further decreasing corrosion risks.

Open loop

An open-loop system is exposed to the atmosphere and draws water directly from the hot or cold water lines it’s connected to. This system features an open expansion tank that accommodates expansion and contraction. Due to its open nature, more evaporation occurs, leading to the introduction of more water and potential contamination.

Open-loop systems, which are less common and often found in older heating systems, cannot typically achieve higher pressures. These systems are prone to allowing pollutants to enter, necessitating periodic cleaning of feed and expansion tanks. This process also introduces oxygen into the system, which can cause corrosion.

The pipework running from the expansion tank to the mechanical room, where the boiler is located, requires careful insulation to prevent freezing.

Flushing a hot water system

New residential hydronic heating systems are closed-loop and should generally not be opened and flushed unless necessary, as oxygenated water can damage them. Regular servicing is essential to maintain efficiency and prevent premature failure, even though these systems may not show obvious signs of trouble. Signs like rumbling noises can indicate mineral buildup. Leaks can introduce oxygenated water, altering the system's pH levels. It's important to check the system's pH annually to decide if flushing is needed. Start with a visual inspection by draining some liquid; if it looks clear, proceed to test the pH with strips or a digital meter, especially for systems with aluminum components.

The correct pH level depends on the composition of the heat exchanger. Systems with a cast-iron, stainless steel, or copper exchanger are resilient and usually have a wide range of acceptable levels. Aluminum is more prone to corrosion and may require a specific pH number. Read the system’s installation and operating manual to determine the acceptable pH range. Using a corrosion inhibitor to balance out the pH is recommended. However, if the buildup or corrosion has been going on for several years, the system will probably not recover with this treatment. Instead, you’ll have to use a cleaner to flush the system to maximize boiler efficiency.

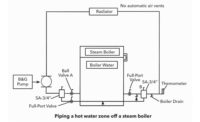

Flushing a steam heating system

Larger steam boilers, once holding thousands of gallons of water, are now more efficient and compact. These boilers heat water into steam, which flows through the system and returns as condensate. However, smaller boilers can run out of water quickly. Modern safety components detect low water levels and shut the boiler down to prevent damage. These include electronic sensors and floaters that monitor water levels, as well as timers that allow water and condensate to return. To address potential corrosion from oxygenated water, these systems require regular flushing to remove mineral buildup. Therefore, it's important to maintain steam boilers and flush them with a cleaner or corrosion inhibitor twice a year, at the start and end of the heating season.

Preventative maintenance

Depending on how dirty the system is and if you don't want to take it out of operation to completely flush it, we recommend using a cleaner that can stay in the system and doesn't require flushing.

Still, be sure to check the pH levels in the system. If the first liquid sample in your visual pH reading contains a lot of rust or sludge, you must take a more aggressive approach by flushing the system with a system restorer. Sludge indicates corrosion in the heat exchanger, fittings or piping.

Here's how to remove sludge:

- Drain off about a gallon of liquid and replace it with three quarts of water and one quart of a system restorer, which removes scaling and sludge deposits.

- Let the solution circulate for two hours.

- After two hours of cycling, dump the system. Leaving the chemical in for too long can damage metal pipes and fittings and ruin the heat exchanger.

- Refill the system with a blend of water and inhibited virgin propylene glycol to prevent corrosion and scale buildup inside the heat exchanger and piping system. Always reference the system manufacturer’s installation and operating manual to ensure you use the proper blend.

Antifreeze

Many contractors use only water in indoor hydronic heating systems. However, water freezes at 32°F; so if there is a power outage, pipes could freeze and burst. Additionally, water also promotes corrosion and mineral buildup.

Adding an inhibited virgin propylene glycol antifreeze to a boiler corrects both of those problems. Installing inhibited virgin propylene glycol into hydronic heating systems is also a requirement to maintain warranty by leading boiler manufacturers.

The type of antifreeze you'll need depends on the climate and the metal content of the system.

The active ingredient of antifreeze is propylene glycol. Avoid antifreeze products that contain "used" propylene glycol, which may introduce minerals and other foreign particles to the boiler. Look for a label that reads "inhibited virgin propylene glycol."