We need to have a new HVAC system for green buildings that can achieve zero CO2 emissions whenever renewable electricity is available. The supply of 100% renewable electricity may not be available until about 2050.

We need to be making our buildings more energy efficient so that smaller amounts of renewable electricity are needed and less capacity needs to be built. This paper presents a new type of HVAC system that reduces energy costs by 36%, reduces CO2 emissions by 34% and reduces capital costs by 27% while using the current supplies of electricity and natural gas. The current use of natural gas boilers can be replaced with electric heat pumps as more renewable electricity is available. This will provide an all-electric HVAC system which consists of electric heat pump chillers for cooling and electric heat pump heaters for heating. When this HVAC system is provided with 100% renewable electricity it will provide zero CO2 emissions.

The solutions to the climate crisis will require both speed and scale. To accomplish these two goals for buildings will require all new buildings and some existing buildings to have the most energy efficient HVAC systems installed. FT Energy Controls (FTEC) has developed a new HVAC system that makes use of HVAC equipment that is already available at scale and provided by many different manufacturers.

Comparison of the Conventional HVAC System and the FTEC HVAC System

Figure 1 shows the conventional chilled water HVAC System that is used for most large commercial buildings and industrial plants. The conventional chilled water HVAC system consists of chillers that provide 45॰F chilled water, DOAS that provide 45॰F dewpoint air and FCUs that are designed for a 10॰F delta T across the cooling coils. In terms of energy efficiencies and capital costs, there are 3 major problems with this conventional system. The first problem is the low delta T of only 10॰F which requires large pipes and high energy costs for pumping. The second problem is the high capital cost for the DOAS and its high fan energy costs created to overcome the pressure drops across the enthalpy wheel, desiccant wheel, cooling coil and reheat coil. The third problem is the energy penalties of having to reheat the air in the DOAS and FCU and the additional capital cost of having two coils in the FCUs. FTEC’s new HVAC system overcomes all three of these problems.

Figure 1: Conventional Chilled Water HVAC System.

Figure 1: Conventional Chilled Water HVAC System.Figure 2 shows FT Energy Controls’ new HVAC system which consists of chillers that provide 38॰F chilled water, ERVs that provide conditioned outdoor air and FCUs that are designed for a 20॰F delta T across the cooling coils. Providing the FCUs with 38॰F chilled water permits the FCUs to condense more moisture from the air and reduce the moisture removal needs from the ERV. Delta T is increased to 20॰F delta T which reduces the piping costs and the pumping energy costs. The DOAS is replaced with an ERV which is only 20% of the capital cost of a DOAS and the fan energy is only about 25% of the fan energy of the DOAS. The ERVs utilize high efficiency, enthalpy wheels which can exchange both moisture and temperature between the conditioned air being exhausted from the building and the outdoor air being added to the building. A high efficiency, enthalpy wheel can make use of the 75॰F air with only 68 grains of moisture to reduce the outdoor air from 94॰F and 119 grains of moisture to 81॰F and 85 grains of moisture before being introduced into the FCU. This provides two-thirds of the temperature reduction and moisture removal needed to get to the room neutral conditions (75॰F and 50% RH). FTEC’s FlowBridge piping package enables the use of a single coil for both cooling and heating and can be controlled so that the need for reheat is avoided. FTEC’s ClimateControl module continuously determines the amounts of outdoor air, the amount of moisture removal and temperature reduction needed for each room and controls the FlowBridge and FCU accordingly. The FlowBridge and ClimateControl allows for a 50% reduction in piping and pumping and an 80% reduction in outdoor air equipment costs.

Figure 3 shows a comparison of the energy consumption for the conventional versus the FTEC HVAC systems. Syska & Hennessy were hired as an expert energy modeling firm to determine the energy use for a 200-room hotel modeled in Chicago, Atlanta and Miami. This chart shows that there are annual energy cost savings of 34% to 38% for the FTEC system for these 3 cities. The energy consumption for cooling, heating, all the fans and pumps are less for the FTEC system. The amounts of cooling and heating for the FTEC systems are less because all reheat energy has been eliminated.

Figure 2: FT Energy Controls’ HVAC System.

Figure 2: FT Energy Controls’ HVAC System. Figure 3: Comparison of annual energy costs for conventional versus FTEC system in Chicago (36% savings), Atlanta (34% savings) and Miami (38% savings).

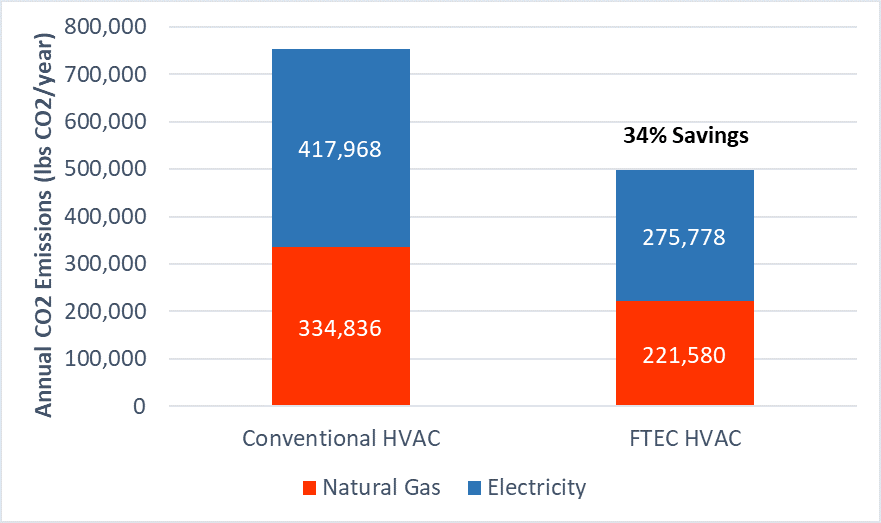

Figure 3: Comparison of annual energy costs for conventional versus FTEC system in Chicago (36% savings), Atlanta (34% savings) and Miami (38% savings). Figure 4 shows a comparison of the annual CO2 emissions for this 200-room hotel for the conventional versus the FTEC HVAC systems. This figure shows that by using the FTEC system rather than the conventional HVAC system the annual CO2 emissions are reduced by 34%. This is due to the increase in the efficiencies of the use of both electricity and natural gas. The current use of natural gas boilers can be replaced with electric heat pumps as more renewable electricity is available. This will provide an all-electric HVAC system which consist of electric heat pump chillers for cooling and electric heat pump heaters for heating. When this HVAC system is provided with 100% renewable electricity it will provide zero CO2 emissions.

The Syska & Hennessy report provided the kilowatt-hour per year and the therms of natural gas per year for each of the three locations. By using the average electric consumption for these three locations multiplied by 0.855 lbs. of CO2 emissions per kilowatt-hour, which is the US average, it is possible to calculate the average CO2 emissions from the use of electricity for this hotel application. By using the average natural gas consumption for these three locations multiplied by 12 lbs. of CO2 emissions per therm of natural gas, it is possible to calculate the average CO2 emissions from the natural gas used for this hotel application.

Figure 4: Comparison of Annual CO2 Emissions for Conventional versus FTEC System for the 200-room hotel case study [basis: 0.855 lbs. CO2 / Kwh; 12 lbs. CO2 / therm].

Figure 4: Comparison of Annual CO2 Emissions for Conventional versus FTEC System for the 200-room hotel case study [basis: 0.855 lbs. CO2 / Kwh; 12 lbs. CO2 / therm].Figure 5 shows the capital cost savings calculated by Gardiner & Theobald for the 200 room hotel example. The FTEC system resulted in a capital cost savings of about 27%. While the chillers are slightly more expensive the savings was more than offset by savings in pumps, piping, ERV, FCUs and controls. The capital cost for the chillers that produce 38॰F chilled water for the FTEC system is about 16% more than the cost for the chillers that produce 45॰F chilled water for the conventional system. The cost for the pumps for the FTEC system is about 6% less than the cost for the conventional system because less chilled water is needed to be pumped with a 20॰F delta T. The cost for the ERV in the FTEC system is about 80% less than the cost for the DOAS in the conventional system. The ERV is a simpler system that only requires an enthalpy wheel while the DOAS requires an enthalpy wheel, a desiccant wheel, cooling coils and reheat coils. The cost for the piping for the FTEC system is about 22% less than the cost of the piping system for the conventional system because the FTEC system requires less volume of chilled water compared to the conventional system. The cost for the FCUs and AHUs for the FTEC system is about 34% less than the cost for the conventional system because the FTEC system uses the same coil for both cooling and heating while the conventional system requires a cooling coil and a separate heating/reheat coil.

Figure 5: Comparison of capital costs for conventional system versus FTEC system in Chicago Atlanta and Miami.

Figure 5: Comparison of capital costs for conventional system versus FTEC system in Chicago Atlanta and Miami. New Technologies - The FlowBridge and ClimateControl

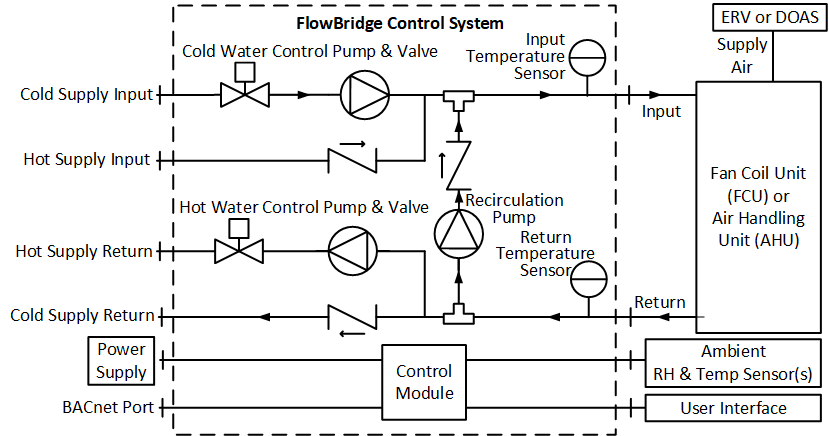

To enable these improvements in energy efficiencies and the reductions in CO2 emissions and reductions in capital costs, it was necessary for FTEC to develop the FlowBridge and ClimateControl. The FlowBridge is a low-cost piping package that controls the temperature and flow rates of water to the fan coil units. ClimateControl is a low-cost control module that continuously determines the amounts of outdoor air, the amount of moisture removal and temperature reduction needed for each room; it controls the FlowBridge and the FCU to deliver these needed amounts.

Figure 6 shows a block flow diagram of the FlowBridge. The FlowBridge is a low-cost piping package consisting of a variable flow rate, chilled water control pump, a variable flow rate, hot water control pump, and a variable flow rate, recirculation pump which enables the mixing of warmer return water from the FCU to be mixed with colder chilled water to adjust the inlet water temperature and flow rate to the coil. Unlike a conventional FCU which is supplied a constant 45॰F chilled water, the FlowBridge supplies variable temperatures of chilled water and variable flow rates of chilled water to each room depending upon the amounts of moisture removal and temperature reduction that is needed. The FlowBridge together with ClimateControl is able to control the delta T and the SHR (Sensible Heat Ratio) for FCU and AHU. Although ASHRAE Standard 90.1 requires a 15॰F Delta T there is a major exemption for individual fan-cooling units with a design supply airflow rate less than 5,000 CFM. The reason for this exemption is the additional cost and complexity of being able to provide a high delta T for units less than 5,000 CFM. The FlowBridge overcomes these costs and complexity by making it possible for higher delta Ts with FCU and AHU of any size. This enables the entire building to operate with a high delta T for lower piping and pumping costs.

Figure 6: The FlowBridge: How it Works.Figure 7 shows a typical FCU with both the FlowBridge and ClimateControl to measure and control the water side and the air side respectively. ClimateControl uses sensors to measure the temperatures, relative humidities and CO2 of the return air (RA), outdoor air (OA) and supply air (SA), and the flowrate of the OA. Low cost sensors together with energy and material balance allow ClimateControl to calculate the amounts of outdoor air, moisture removal and temperature reduction needed in each room.

Figure 6: The FlowBridge: How it Works.Figure 7 shows a typical FCU with both the FlowBridge and ClimateControl to measure and control the water side and the air side respectively. ClimateControl uses sensors to measure the temperatures, relative humidities and CO2 of the return air (RA), outdoor air (OA) and supply air (SA), and the flowrate of the OA. Low cost sensors together with energy and material balance allow ClimateControl to calculate the amounts of outdoor air, moisture removal and temperature reduction needed in each room. Figure 7: Climate Control: How it Works.In summary, FT Energy Controls’ FlowBridge and ClimateControl:

Figure 7: Climate Control: How it Works.In summary, FT Energy Controls’ FlowBridge and ClimateControl:- Reduces the size of piping and pumping by 50% for the entire building;

- Saves 80% of the equipment costs to condition the outdoor air;

- Enables use of a single coil for both cooling and heating;

- Makes use of a low-cost control system for each room which controls the FCU to deliver the required amounts of outdoor air, moisture removal and temperature control; and

- In total, reduces HVAC system energy costs by 36%, CO2 emissions by 34%, and capital costs by 27% while using the current supplies of electricity and natural gas.