Refrigeration

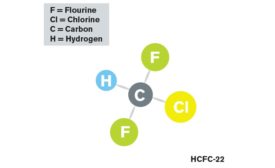

What was once an alternative refrigerant is now an industry mainstay

Read More

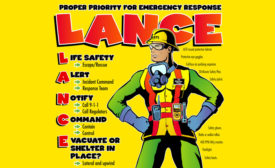

The First 10 Minutes Are Critical in an Ammonia Release

Knowing what not to do is just as important as knowing what to do

Read More

Equipment Placement is Important When it Comes to Walk-ins

Location of the condensing unit and evaporator are key to a successful installation

Read More

Honeywell Starts Up $300 Million Refrigerant Production Facility

Louisiana site will produce HFO-1234yf for automobile applications

June 5, 2017

Axiom Energy’s Refrigeration Battery Wins American Business Award

Thermal energy storage provides supermarkets with long-duration load shifting

June 5, 2017

Dynatemp Restructures Executive Leadership Team

Company names Brad Kivlan named CEO, makes other leadership appointments

June 5, 2017

Alliance Head Urges Pruitt and Tillerson to Honor Montreal Protocol

Alliance for Responsible Atmospheric Policy’s Kevin Fay cites numerous benefits to U.S.

June 5, 2017

Contemplating the Yin and Yang of DOE Regs

Conversations on a trade show floor include some surprises

Read More

First 100 Days: Where Do We Go from Here?

What does the future of the HVACR industry have in store?

Read More

Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing