Refrigeration

Researchers must look beyond nonflammable chemicals

Read More

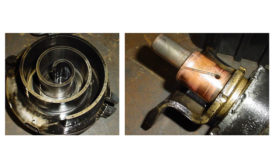

Troubleshooting a Compressor Burnout

Compressor burnouts are rare but knowing how to deal with them is essential

Read More

Is R-410A Here to Stay?

In a world of phaseouts and phasedowns, R-410A seems safe – for now

Read More

Demand Response and Smart-grid Technologies in Supermarkets

Intelligent refrigeration system managers turn equipment into assets

Read More

Troubleshooting Filter Driers — Part 2

How to identify and repair restrictions and damage in the liquid line

March 6, 2017

Understanding Electronic Controls a Key to Successful Service

The saying ‘knowledge is power’ holds very true for refrigeration technicians

Read More

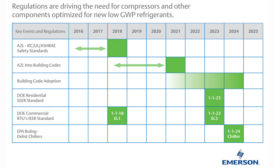

Low-GWP Refrigerants a ‘Megatrend’ in Commercial HVAC

When it comes to refrigerants, change is a constant

Read More

Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing