Refrigeration

The devil is in the details, and the wrong choice can cause issues now or in the future

Read More

What’s the Latest with R-404A?

As another industry workhorse feels the GWP crunch, contractors look at alternatives

Read More

The Value of Refrigerant Recovery Incentives

Is pay to play a proper way to increase reclaim rates in preparation of the final R-22 phaseout deadline?

April 10, 2017

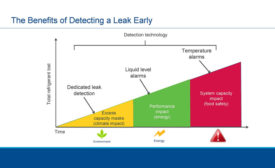

Beat Leaks with Detection, Notification, and Monitoring

Leak-control programs spur reclamation by keeping refrigerant in the system

Read More

Former ASHRAE President Thomas Watson Honored by Institute of Refrigeration

Receives J&E Hall Gold Medal Award for work with chillers, heat pumps

April 4, 2017

DFW Airport Adding Cargo Refrigeration Facilities

New cold chain storage equipment optimizes airport for shipping perishable goods

April 4, 2017

Spring is Here! But the R-22 Isn’t

What’s behind the low reclaim numbers, and what can the industry do about it?

Read More

Taking the ‘Trouble’ Out of Troubleshooting

The right attitude and a willingness to learn can make tough jobs easier

April 3, 2017

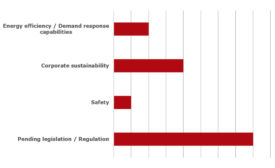

CO2 Refrigerant: Acceptance Grows, Challenges Remain

Survey points out drivers, barriers in commercial and industrial applications

Read More

Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing